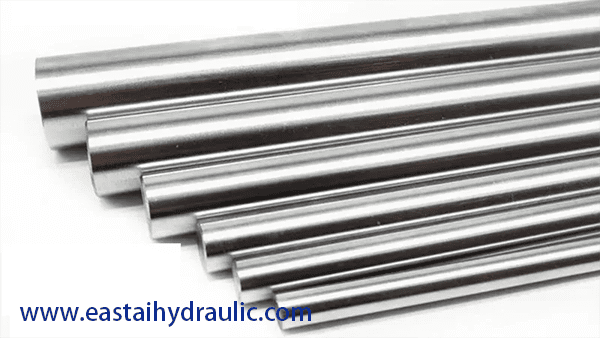

1045 Chrome Plated Bar

1045 steel, renowned for its medium carbon content, offers an ideal balance between strength, ductility, and ease of machining, making it a preferred choice for many industrial applications. When enhanced with a chrome plating, the bar not only gains in aesthetic appeal but also in corrosion resistance and surface hardness, broadening its utility in harsh environments.

Properties of 1045 Chrome Plated Bar

The chemical composition of 1045 steel includes carbon, manganese, phosphorus, sulfur, and iron, providing a solid foundation for strength and machinability. Its mechanical properties include a commendable tensile strength and impact resistance, while the chrome plating adds to its corrosion resistance and improves its surface finish.

Applications of 1045 Chrome Plated Bars

From its use in hydraulic pistons to its role in automotive suspension components, the versatility of the 1045 chrome plated bar is evident across various industries. Its durability and resistance to wear make it a staple in the manufacturing of precision parts and equipment.

Manufacturing Process

The journey from raw steel to a finished chrome plated bar involves several steps: steel making, forming, heat treatment, and finally, chrome plating. Each stage is crucial in achieving the desired properties and quality of the final product.

Quality and Standards

Adherence to strict quality assurance measures and industry standards is essential in the production of 1045 chrome plated bars. This ensures that the products not only meet but exceed the expectations in terms of performance and reliability.

Advantages Over Other Materials

When compared to other materials, 1045 chrome plated bars stand out due to their enhanced durability, cost-effectiveness, and minimal environmental impact. These advantages make them an attractive option for both manufacturers and consumers.

Maintenance and Care

To ensure the longevity and optimal performance of chrome plated bars, routine maintenance is necessary. This includes regular inspections, cleaning, and the application of protective coatings as needed.

Buying Guide for 1045 Chrome Plated Bars

Choosing the right chrome plated bar involves considering factors such as size, strength requirements, and environmental conditions. Knowing where to purchase quality bars can also make a significant difference in the outcome of projects.

Innovations and Future Trends

The field of material science constantly evolves, bringing forth technological advancements that enhance the properties and applications of 1045 chrome plated bars. Staying abreast of these trends can open up new possibilities for innovation.

Challenges and Solutions

Despite their many benefits, working with 1045 chrome plated bars can present challenges, such as issues with plating adherence or corrosion under extreme conditions. Understanding these potential problems and knowing how to address them is crucial for success.

Case Studies

Examining real-world applications and the performance of 1045 chrome plated bars in various settings can provide valuable insights into their versatility and reliability.

The 1045 chrome plated bar stands as a testament to the advancements in material science and engineering. With its blend of strength, durability, and aesthetic appeal, it continues to play a pivotal role in the success of numerous industrial and automotive applications.