HARD CHROME PLATE SHAFTS | CHROME PLATE SHAFTING

Home »» HARD CHROME PLATE SHAFTS | CHROME PLATE SHAFTING

Hard chrome plated shafts, often referred to as chrome plated rods or bars, are typically crafted from steel rods. These rods undergo a meticulous process of precision grinding and polishing before being coated with a layer of hard chrome. This chrome plating varies in thickness, commonly around 20 to 25 microns, although other specifications are available to suit different requirements. Our factory, with over 20 years of expertise, stands as a premier manufacturer and supplier of these high-quality chrome plated shafts in China. We are committed to delivering exceptional products that meet a wide range of industrial needs.

PRODUCT SUMMARY

PRODUCT NAME: HARD CHROME PLATED SHAFTS

Manufacturer Name: EASTAI

Place of Origin: China

Materials Available: CK45 / C45 / SAE 1045; SAE 4140 / 42CrMo; Stainless Steel 304, 316

Size Range: Diameter 6 mm — 1000 mm, Equivalent Imperial Sizes Available.

PRODUCT DETAILS OF HARD CHROME PLATED SHAFTS

As one of the leading chrome plated rod manufacturers, our factory produces and supplies hard chrome plated shafts with details as below.

PRODUCT STANDARDS

Our chrome plated shafts are produced upon customers’ specification, and meet belowstandards.

- ASTM A108

- ASTM A311

- Other popular standards.

CHEMICAL COMPOSITION OF HARD CHROME PLATED SHAFTS

As a distinguished manufacturer and supplier in the chrome plated bar industry, we offer hard chrome plated shafts crafted from medium carbon steel grades, tailored to meet customer requirements. Our most sought-after steel grades include AISI 1045, JIS S45C, SAE1045, DIN CK45, SAE 4140, and 42CrMo, among others.

Presented below is the chemical composition for the widely-used steel grade SAE 1045 / CK45:

| Steel Grade | Chemical Composition % | ||||

| Carbon | Mn | Si | P | S | |

| SAE 1045 | 0.43-0.50 | 0.60-0.90 | – | 0.040 Max | 0.050 Max |

| CK 45 | 0.42-0.50 | 0.50-0.80 | 0.40 Max | 0.035 Max | 0.035 Max |

And below is the chemical composition of 4140 chrome plated shafting.

| SAE 4140 | C% | Si% | Mn% | P% | S% | Cr% | Mo% |

| Min | 0.36 | 0.1 | 0.65 | 0.75 | 0.15 | ||

| Max | 0.44 | 0.4 | 1.1 | 0.04 | 0.04 | 1.2 | 0.35

|

MECHANICAL PROPERTIES OF CHROME PLATED SHAFTING

| Steel Grade | Mechanical Properties | |||

| Yield Strength | Tensile Strength | Elongation | Hardness | |

| SAE 1045 | 75000 psi / 517 Mpa | 85000 psi / 585Mpa | 10% | Rc 60-72 |

| CK 45 | 75000 psi / 517 Mpa | 85000 psi / 585Mpa | 10% | Rc 60-72 |

Through specialized heat treatment, our chrome plated shafts achieve a minimum yield strength of 100K psi (690 Mpa), ensuring durability and performance.

For applications demanding high strength, we offer the 4140 hard chrome plated rod. Below, you will find the detailed chemical properties of SAE 4140, reflecting its robustness and quality.

| 4140 | Yield strength | Tensile Strength | Elongation | Hardness HB |

| Min | 800 Mpa /115K psi | 900 Mpa /130K psi | 20% | 270 HB |

HARD CHROME PLATED THICKNESS

Our chrome plated shafting typically features a minimum chrome plating thickness of 20 Microns (0.0008″). Additional thicknesses, up to a maximum of 50 Microns, are available upon customer request. Our chrome steel rods are rigorously tested, passing a minimum of 48 hours in salt spray tests as per ASTM B-117 standards, demonstrating their superior corrosion resistance.

APPLICATION OF CHROME PLATED SHAFTS

Chrome plated steel rods are essential components in various industrial applications, including:

- Chrome plated steel rods are essential components in various industrial applications, including:

- Hydraulic Shafting: Integral for the smooth operation of hydraulic systems.

- Pneumatic Piston Rods: Key elements in pneumatic devices for mechanical motion.

- Pump Shafting: Crucial for the stability and efficiency of pump systems.

- Machinery Shafts: Utilized in various machines, such as center shafts for textile and transport machinery.

- Rollers for Machines: Vital in machines like packing and printing machines, enhancing their functionality and efficiency.

Additionally, apart from solid steel rods, chrome plated shafts can also be crafted from chrome plated hollow bars, offering versatility and adaptability to diverse industrial needs.

CHROME PLATED SHAFTING DIMENSIONS

As a prominent manufacturer and supplier of chrome plated piston rods, we produce chrome plated shafts with an outer diameter of up to 1000 mm. Below is a list of some commonly requested diameter dimensions.

| Diameter(imperial size) | Weight per Foot | Diameter(metric size) | Weight per Meter | ||||||||

| (Inches) | (Lbs.) | mm | (KG.) | ||||||||

| 0.375 | 0.375 | 10 | 0.62 | ||||||||

| 0.438 | 0.512 | 12 | 0.89 | ||||||||

| 0.5 | 0.668 | 14 | 1.21 | ||||||||

| 0.625 | 1.043 | 15 | 1.39 | ||||||||

| 0.688 | 1.264 | 16 | 1.58 | ||||||||

| 0.75 | 1.502 | 17 | 1.78 | ||||||||

| 0.875 | 2.044 | 18 | 2 | ||||||||

| 0.938 | 2.349 | 20 | 2.47 | ||||||||

| 1 | 2.67 | 22 | 2.98 | ||||||||

| 1.063 | 3.017 | 25 | 3.85 | ||||||||

| 1.125 | 3.379 | 28 | 4.83 | ||||||||

| 1.188 | 3.768 | 30 | 5.55 | ||||||||

| 1.25 | 4.172 | 32 | 6.31 | ||||||||

| 1.313 | 4.603 | 35 | 7.55 | ||||||||

| 1.375 | 5.048 | 36 | 7.99 | ||||||||

| 1.5 | 6.008 | 40 | 9.86 | ||||||||

| 1.563 | 6.523 | 45 | 12.48 | ||||||||

| 1.625 | 7.05 | 50 | 15.41 | ||||||||

| 1.688 | 7.608 | 55 | 18.65 | ||||||||

| 1.75 | 8.177 | 56 | 19.33 | ||||||||

| 1.875 | 9.387 | 60 | 22.19 | ||||||||

| 1.938 | 10.028 | 63 | 24.47 | ||||||||

| 2 | 10.68 | 65 | 26.05 | ||||||||

| 2.125 | 12.057 | 70 | 30.21 | ||||||||

| 2.25 | 13.517 | 75 | 34.68 | ||||||||

| 2.375 | 15.06 | 80 | 39.46 | ||||||||

| 2.5 | 16.688 | 85 | 44.54 | ||||||||

| 2.625 | 18.398 | 90 | 49.94 | ||||||||

| 2.75 | 20.192 | 95 | 55.64 | ||||||||

| 2.875 | 22.069 | 100 | 61.65 | ||||||||

| 3 | 24.03 | 105 | 67.97 | ||||||||

| 3.25 | 28.202 | 110 | 74.6 | ||||||||

| 3.375 | 30.413 | 115 | 81.53 | ||||||||

| 3.5 | 32.708 | 120 | 88.78 | ||||||||

| 3.625 | 35.085 | 125 | 96.33 | ||||||||

| 3.75 | 37.547 | 130 | 104.19 | ||||||||

| 4 | 42.72 | 140 | 120.83 | ||||||||

| 4.25 | 48.227 | 150 | 138.71 | ||||||||

| 4.5 | 54.068 | 160 | 157.82 | ||||||||

| 4.75 | 60.242 | 170 | 178.17 | ||||||||

| 5 | 66.75 | 180 | 199.75 | ||||||||

| 5.25 | 73.592 | 200 | 246.6 | ||||||||

| 5.5 | 80.768 | 250 | 385.31 | ||||||||

| 6 | 96.12 | ||||||||||

| 6.5 | 112.808 | ||||||||||

| 7 | 130.83 | ||||||||||

| 7.5 | 150.188 | ||||||||||

| 8 | 170.88 | ||||||||||

| 8.5 | 192.908 | ||||||||||

| 9 | 216.27 | ||||||||||

| 10 | 267 | ||||||||||

| 11 | 323.07 | ||||||||||

| 12 | 384.48 | ||||||||||

| Note: Other sizes are available on customer’s request, Our Chrome rod max size is diameter 1000 mm. | |||||||||||

LENGTH

Our facility specializes in producing chrome plated shafts with a maximum length of 12 meters. We offer both random length shafts and fixed length options, with the capability to precisely cut shafts to the desired length as per customer specifications.

HARD CHROME PLATED SHAFTS TOLERANCE

Our range of chrome plated shafts is available with precision diameter tolerances including g6, f7, f8, and f9, tailored to meet specific customer requirements. Below, you will find the detailed tolerance chart for these specifications.

| Tolerances for Chrome Shafts (ISO 286-2) | |||||||||||

| over | up to | Upper and Lower limits in micrometer (0.001 mm) | |||||||||

| d9 | e8 | f7 | g6 | h5 | h6 | h7 | h8 | h9 | h11 | ||

| – | 3 | -20 | -14 | -6 | -2 | 0 | 0 | 0 | 0 | 0 | 0 |

| -45 | -28 | -16 | -8 | -4 | -6 | -10 | -14 | -25 | -60 | ||

| 3 | 6 | -30 | -20 | -10 | -4 | 0 | 0 | 0 | 0 | 0 | 0 |

| -60 | -38 | -22 | -12 | -5 | -8 | -12 | -18 | -30 | -75 | ||

| 6 | 10 | -40 | -25 | -13 | -5 | 0 | 0 | 0 | 0 | 0 | 0 |

| -76 | -47 | -28 | -14 | -6 | -9 | -15 | -22 | -36 | -90 | ||

| 10 | 18 | -50 | -32 | -16 | -6 | 0 | 0 | 0 | 0 | 0 | 0 |

| -93 | -59 | -34 | -17 | -8 | -11 | -18 | -27 | -43 | -110 | ||

| 18 | 30 | -65 | -40 | -20 | -7 | 0 | 0 | 0 | 0 | 0 | 0 |

| -117 | -73 | -41 | -20 | -9 | -13 | -21 | -33 | -52 | -130 | ||

| 30 | 50 | -80 | -50 | -25 | -9 | 0 | 0 | 0 | 0 | 0 | 0 |

| -142 | -89 | -50 | -25 | -11 | -16 | -25 | -39 | -62 | -160 | ||

| 50 | 65 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 65 | 80 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

| -174 | -106 | -60 | -29 | -13 | -19 | -30 | -46 | -74 | -190 | ||

| 80 | 100 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 100 | 120 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

| -207 | -126 | -71 | -34 | -15 | -22 | -35 | -54 | -87 | -220 | ||

| 120 | 140 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 140 | 160 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 160 | 180 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

| -245 | -148 | -83 | -39 | -18 | -25 | -40 | -63 | -100 | -250 | ||

| 180 | 200 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 200 | 225 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 225 | 250 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

| -285 | -172 | -96 | -44 | -20 | -29 | -46 | -72 | -115 | -290 | ||

| 250 | 280 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 280 | 315 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

| -320 | -191 | -108 | -49 | -23 | -32 | -52 | -81 | -130 | -320 | ||

| 315 | 355 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

| 355 | 400 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

| -350 | -214 | -119 | -54 | -25 | -36 | -57 | -89 | -140 | -360 | ||

OUR CHROME PLATED SHAFTS: RECOGNIZED FOR THEIR DISTINCTIVE FEATURES

a. The hard chrome surface of our shafts provides exceptional corrosion and wear resistance, combined with a very smooth finish, resulting in a low coefficient of friction. This not only ensures functionality but also offers an aesthetically pleasing and durable appearance.

b. The use of carbon steel in our shafts strikes an optimal balance between durability, hardness, and wear resistance, while maintaining formability, weldability, and robustness.

c. Precision-engineered to high tolerances, our shafts are ideal for hydraulic piston applications, ensuring precise fitment with the cylinder.

d. Our chrome plated shafts boast a high level of strength, with yield strengths ranging from 75,000 psi to 100,000 psi, depending on the material and heat treatment employed.

e. Superior Hardness: The surface hardness of our shafts reaches a minimum of HV850, enhancing wear resistance and extending the lifespan, which in turn provides cost savings for our customers.

f. Excellent Surface Smoothness: Our hard chrome plated shafting has a surface roughness of around Ra0.2μm (8 Ra), with a maximum of Ra0.4μm (16 Ra), ensuring a high-quality finish.

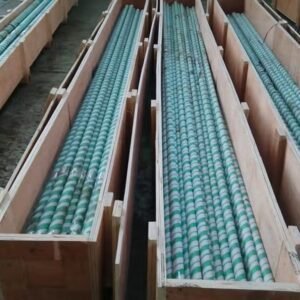

Before dispatch, each of our chrome plated shafts is meticulously coated with anti-rust oil to ensure long-term preservation. To further safeguard the integrity of the chromed surface, particularly on piston rods, we employ a protective cardboard (paper pipe) wrapping for each individual rod. This careful attention to detail extends to our shipping practices, where we utilize robust, seaworthy packaging options like wooden cases or secure rope wraps, guaranteeing the safe and intact delivery of our products.

- Honed Tube

- Ready to Honed Tube

- Cold Drawn Seamless Tube

- 34CrMo / 34CrMo4 Seamless Steel Tube

- SRB (Skived and RollerBurnished) Tube/Pipe

- Chrome Plated Bar

- Hollow Chrome Plated Bar

- Linear Motion Shaft

- Stainless Steel Cylinder Rod

- Induction Hardened Chrome Plated Bar

- SAE4140 Hot Rolled Round Steel Bar

- Custom Hydraulic Cylinder

- Honed Tube

- Ready to Honed Tube

- Cold Drawn Seamless Tube

- 34CrMo / 34CrMo4 Seamless Steel Tube

- SRB (Skived and RollerBurnished) Tube/Pipe

- Chrome Plated Bar

- Hollow Chrome Plated Bar

- Linear Motion Shaft

- Stainless Steel Cylinder Rod

- Induction Hardened Chrome Plated Bar

- SAE4140 Hot Rolled Round Steel Bar

- Custom Hydraulic Cylinder