Products List

- Honed Tube

- Ready to Honed Tube

- Cold Drawn Seamless Tube

- 34CrMo / 34CrMo4 Seamless Steel Tube

- SRB (Skived and RollerBurnished) Tube/Pipe

- Chrome Plated Bar

- Hollow Chrome Plated Bar

- Linear Motion Shaft

- Stainless Steel Cylinder Rod

- Induction Hardened Chrome Plated Bar

- SAE4140 Hot Rolled Round Steel Bar

- Custom Hydraulic Cylinder

- Honed Tube

- Ready to Honed Tube

- Cold Drawn Seamless Tube

- 34CrMo / 34CrMo4 Seamless Steel Tube

- SRB (Skived and RollerBurnished) Tube/Pipe

- Chrome Plated Bar

- Hollow Chrome Plated Bar

- Linear Motion Shaft

- Stainless Steel Cylinder Rod

- Induction Hardened Chrome Plated Bar

- SAE4140 Hot Rolled Round Steel Bar

- Custom Hydraulic Cylinder

Email:info@east-ai.cn

Tel:+86 13771039951

Contact: Jeff

Contact Me

Provide detailed contact information to ensure we can reach you effectively.

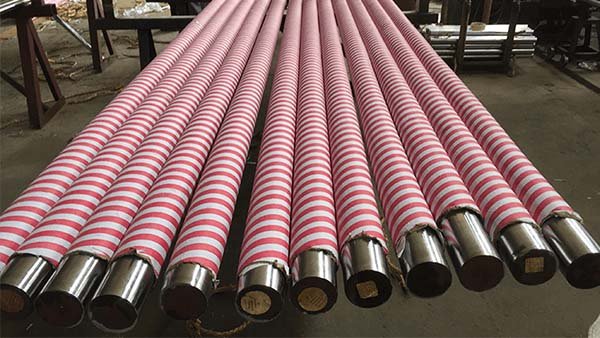

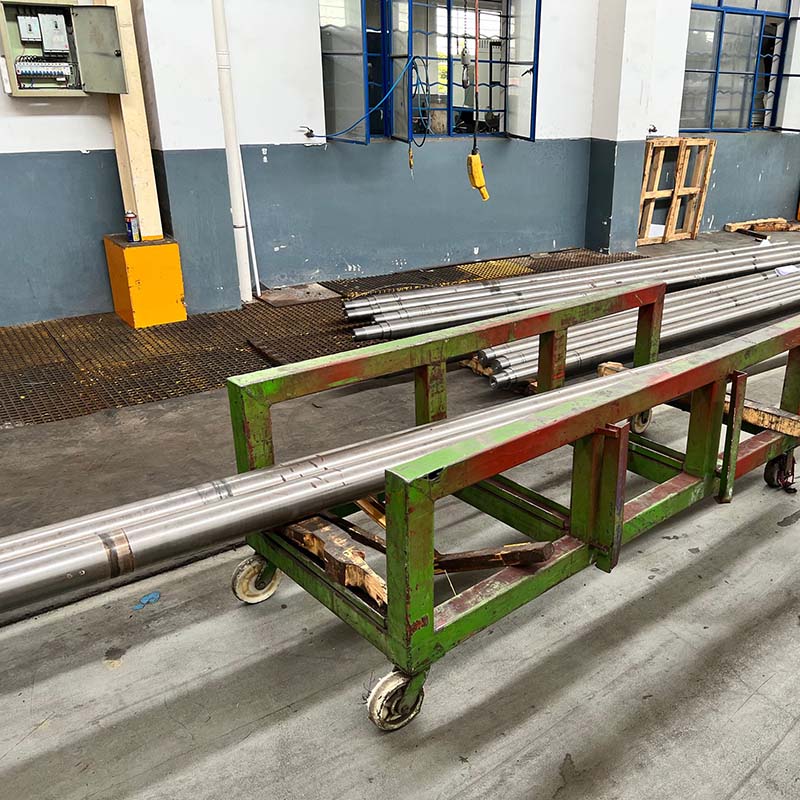

Chrome Plated Bar

As a premier manufacturer and supplier specializing in chrome-plated bars, EASTAI Hydraulic has dedicated over 15 years to providing and exporting top-quality hydraulic cylinder chrome bars and hydraulic piston rods from China. Chrome-plated rods are primarily used in the manufacturing of hydraulic and pneumatic cylinders, offering enhanced durability and resistance to wear and corrosion. These rods find widespread applications in the automotive industry, particularly in shock absorbers, steering columns, and other critical components. Should you have any inquiries or encounter any issues, please do not hesitate to contact us at jeff@east-ai.cn. We guarantee a response within one working day.

Material: CK45, SAE1045, 4140, 4130, 4340, SAE1518, SAE4145, JIS45C, 40Cr, 20MnV6, 42CrMo, SS431, SS430, Stainless Steel 304/316/2205, etc.

Diameter: Φ 6-500mm

Length: max 20 meters

Salt Spray Test: Passed As Per Request

Chrome Layer: min 20/25/30/50 Micron or customized

Hardness of Chrome Layer: 850 HV (min) – 1150 HV

Roughness: Ra <= 0.4

Straightness: <= 0.5/1000

Diameter Tolerance: ISO f7/f8/f9/h8/h9 or as request

Roundness: Half of the tolerance ISO f7

Heat Treatment Type: 1) Normal no heat 2) Q+T (Quenched + Tempered) 3) Induction Hardened

Product Offerings: Hard Chrome Bar, Hard Chrome Rod, Induction Hardened Chrome Bar, Hydraulic Cylinder Shaft, Hydraulic Cylinder Rod.

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% | ||

| Ck45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | |||

| ST52 | ≤0.22 | ≤1.6 | ≤0.55 | ≤0.04 | ≤0.04 | 0.02-0.15 | |||

| 20MnV6 | 0.17-0.24 | 1.30-1.70 | 0.10-0.50 | ≤0.035 | ≤0.035 | 0.10-0.20 | ≤0.30 | ||

| 42CrMo4 | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | 0.07-0.12 | 0.90-1.20 | ||

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | 0.80-1.10 | |||

| Material | T.S N/MM2 | Y.S N/MM2 | E%(MIN) | CHARPY | CONDITION | |||

| CK45 | 610 | 355 | 15 | >41J | NORMALIZE | |||

| CK45 | 800 | 630 | 20 | >41J | Q+T | |||

| ST52 | 500 | 355 | 22 | NORMALIZE | ||||

| 20MnV6 | 750 | 590 | 12 | >40J | NORMALIZE | |||

| 42CrMo4 | 980 | 850 | 14 | >47J | Q+T | |||

| 40Cr | 1000 | 800 | 10 | Q+T | ||||

| Grade of tolerance Dia mm o | f | h | ||||

| f7 | f8 | g6 | h7 | h8 | h9 | |

| 3mm | -0.006 -0.016 | -0.006 -0.020 | -0.002 -0.008 | 0 -0.010 | 0 -0.014 | 0 -0.025 |

| 3mm-6mm | -0.010 -0.022 | -0.010 -0.028 | -0.004 -0.012 | 0 -0.012 | 0 -0.018 | 0 -0.030 |

| 6mm-10mm | -0.013 -0.028 | -0.013 -0.035 | -0.005 -0.014 | 0 -0.015 | 0 -0.022 | 0 -0.036 |

| 10mm-18mm | -0.016 -0.034 | -0.016 -0.043 | -0.006 -0.017 | 0 -0.018 | 0 -0.027 | 0 -0.043 |

| 18mm-30mm | 0.020 -0.041 | -0.020 -0.053 | -0.007 -0.020 | 0 -0.021 | 0 -0.033 | 0 -0.052 |

| 30mm-50mm | -0.025 -0.050 | -0.025 -0.064 | -0.009 -0.025 | 0 -0.025 | 0 -0.039 | 0 -0.062 |

| 50mm-80mm | -0.030 -0.060 | -0.030 -0.079 | -0.010 -0.029 | 0 -0.030 | 0 -0.046 | 0 -0.074 |

| 80mm-120mm | -0.036 -0.071 | 0.036 -0.090 | 0.012 -0.034 | 0 -0.035 | 0 -0,054 | 0 0.087 |

| 120mm-180mm | -0.043 -0.083 | -0.043 -0.106 | -0.014 -0.039 | 0 -0.040 | 0 -0.063 | 0 -0.100 |

| 180mm-250mm | -0.050 -0.096 | -0.050 0.122 | -0.015 0.044 | 0 -0.046 | 0 -0.072 | 0 -0.115 |

| 250mm-315mm | -0.056 -0.108 | -0.056 -0.137 | -0.017 -0.049 | 0 -0.052 | 0 -0.081 | 0 -0.130 |

| 315mm-400mm | -0.062 -0.119 | -0.062 -0.151 | -0.018 -0.054 | 0 -0.057 | 0 -0.089 | 0 -0.140 |

| 400mm-500mm | -0.068 -0.131 | -0.068 -0.165 | -0.020 -0.060 | 0 -0.063 | 0 -0.097 | 0 -0.155 |

Piston Rod Production Process

Delivery Condition:

- Hard Chrome Piston Rod

- Quenched & Tempered (Q+T) Rod

- Induction Hardened Rod

- Q+T Induction Hardened Rod

Corrosion Resistance:

Test in natural salt spray according to ASTM B 117-96 hours.

Professional Testing

Contact Me

Features of Our Chrome Plated Bar/Chrome Rod/Chrome Shaft:

Precision Manufacturing: We strictly follow customer drawings, packing, and quality requests to ensure precision in every part.

Tight Tolerances: Our processes allow for tolerances to be kept within +/-0.01mm, ensuring high precision.

Quality Assurance: Utilization of the most advanced inspection tools to maintain quality.

Expertise: Our team consists of experienced engineers and well-trained workers, guaranteeing expert craftsmanship.

Timely Delivery: We commit to fast and timely delivery, providing speedy and professional service.

Cost-Saving Advice: We offer professional suggestions during the design process to help customers save costs.

Our Main Business Range

Carbon Seamless Steel Pipe/Tube

Hydraulic Cylinder Tube (Honed Tube)

Hard Chrome Plated Rod/Bar/Shaft (Hydraulic Piston Rod)

Chrome Plated Bars/Chrome Plated Rods & Shafting

4140 Chrome Plated Bars & Rods

1045 Hard Chrome Bars

We pride ourselves on offering the best hard chrome rods and chrome bars for our customers. If you are interested in our chrome-plated rods, hard chrome rod, or induction hardened chrome bars, please don’t hesitate to get in touch for more information.

Contact Me

Email: info@east-ai.cn

Tel, WhatsApp, WeChat:+86 13771039951