In the world of mechanical engineering, stainless steel piston rods play a crucial role. These components are essential for various applications, from automotive engines to hydraulic systems. In this guide, we’ll delve deep into what makes stainless steel piston rods so vital, their types, manufacturing processes, benefits, and more.

What is a Stainless Steel Piston Rod?

Basic Definition

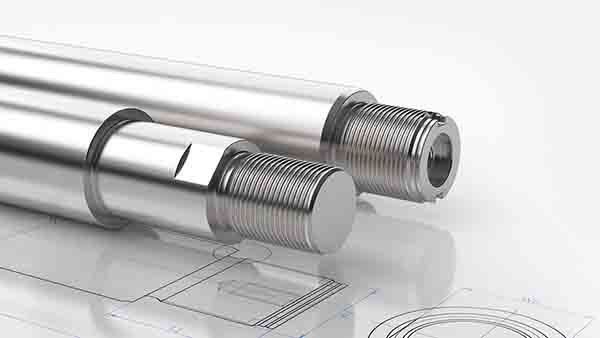

A stainless steel piston rod is a cylindrical rod made from stainless steel, designed to transfer force in a straight line within mechanical systems. It’s a critical component in systems where movement needs to be controlled precisely, such as in engines and hydraulic cylinders.

Key Characteristics

Stainless steel piston rods are known for their exceptional strength, corrosion resistance, and ability to withstand high pressure and temperatures. These properties make them ideal for demanding environments.

Types of Stainless Steel Used in Piston Rods

304 Stainless Steel

304 stainless steel is a popular choice for piston rods due to its excellent corrosion resistance and good mechanical properties. It’s commonly used in environments where exposure to corrosive substances is minimal.

316 Stainless Steel

For more corrosive environments, 316 stainless steel is preferred. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion. This makes it suitable for marine and chemical applications.

Other Grades

Other grades, like 410 and 420 stainless steel, are also used in specific applications where higher hardness and wear resistance are required. Each grade offers unique properties that cater to different industrial needs.

Manufacturing Process of Stainless Steel Piston Rods

Raw Material Selection

The process begins with selecting the appropriate grade of stainless steel, considering factors like the intended application and environmental conditions.

Forging and Machining

The stainless steel is then forged and machined to precise dimensions. This involves cutting, drilling, and shaping the material to meet the specific design requirements.

Heat Treatment and Surface Finishing

Heat treatment is applied to enhance the mechanical properties of the piston rod, followed by surface finishing processes like polishing or plating to improve corrosion resistance and reduce friction.

Advantages of Using Stainless Steel Piston Rods

Corrosion Resistance

One of the primary advantages of stainless steel piston rods is their resistance to corrosion. This makes them ideal for use in harsh environments where other materials might fail.

Strength and Durability

Stainless steel is known for its strength and durability, which ensures that piston rods can withstand high pressures and loads without deforming or breaking.

Maintenance and Longevity

The low maintenance requirements and long lifespan of stainless steel piston rods make them a cost-effective choice in the long run, despite the higher initial investment.

Applications of Stainless Steel Piston Rods

Automotive Industry

In the automotive sector, stainless steel piston rods are used in shock absorbers, engines, and other critical components where durability and performance are paramount.

Hydraulic Systems

Hydraulic systems rely on piston rods to transfer force and control movement accurately. Stainless steel rods are preferred for their reliability and resistance to wear.

Marine and Offshore

Given their excellent resistance to saltwater corrosion, stainless steel piston rods are extensively used in marine and offshore applications, including oil rigs and ships.

Challenges and Considerations

Cost Factors

While stainless steel piston rods offer numerous benefits, they are generally more expensive than those made from other materials. It’s essential to weigh the cost against the performance requirements.

Material Compatibility

Ensuring compatibility with other materials in the system is crucial. Incompatible materials can lead to galvanic corrosion or other issues that might compromise the system’s integrity.

Environmental Impact

Consideration of the environmental impact of manufacturing and disposing of stainless steel piston rods is increasingly important. Recycling and sustainable practices can mitigate some of these concerns.

Innovations in Stainless Steel Piston Rod Technology

Coatings and Surface Treatments

Recent advancements include various coatings and surface treatments that enhance the performance of stainless steel piston rods, such as reducing friction or increasing wear resistance.

Composite Material Integration

Integrating composite materials with stainless steel piston rods can lead to lighter and more robust components, offering a blend of strength and reduced weight.

How to Select the Right Stainless Steel Piston Rod

Assessing Application Needs

Understanding the specific requirements of the application is the first step in selecting the right piston rod. Consider factors like load, pressure, environmental conditions, and expected lifespan.

Consulting with Experts

Working with experts or manufacturers can provide valuable insights and recommendations, ensuring that the selected piston rod meets all performance and safety criteria.

Stainless steel piston rods are indispensable in many industries due to their strength, durability, and resistance to corrosion. By understanding their types, manufacturing processes, and applications, you can make informed decisions about their use in your projects.