HOW TO MEASURE A HYDRAULIC CYLINDER?

When dealing with hydraulic systems, accuracy is paramount. One of the most critical aspects of maintaining these systems is correctly measuring the hydraulic cylinder. Whether you’re a seasoned professional or a DIY enthusiast, knowing how to measure a hydraulic cylinder accurately can save you time, money, and a lot of frustration. In this guide, we’ll walk you through the step-by-step process, ensuring you’re well-equipped to handle the task with confidence. Along the way, we’ll discuss various hydraulic cylinder dimensions, including the cylinder rod diameter, cylinder bore size, and overall hydraulic cylinder length.

What is Hydraulic Cylinders?

Before diving into the measurement process, it’s essential to understand what a hydraulic cylinder is and the role it plays in various machines and systems. Essentially, a hydraulic cylinder is a mechanical actuator used to provide unidirectional force through a unidirectional stroke. It’s a vital component in construction equipment, manufacturing machinery, and even automotive systems. Understanding the hydraulic cylinder dimensions is crucial for ensuring proper fit and function within your system.

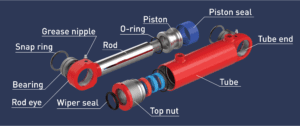

Key Components of a Hydraulic Cylinder

To measure a hydraulic cylinder accurately, you must first familiarize yourself with its main components.

- Cylinder Body: The large, cylindrical tube that houses the piston and holds the hydraulic fluid.

- Piston: The internal component that moves back and forth inside the cylinder body, creating pressure and movement.

- Rod: The shaft connected to the piston that extends out of the cylinder to deliver force to the application.

Why Accurate Measurement is Crucial?

Precision measurement of hydraulic cylinders is not just about getting the numbers right; it’s about ensuring the efficiency and safety of the entire hydraulic system. An inaccurately measured cylinder can lead to improper fitting, which might cause leaks, reduced system performance, or even complete failure. When measuring hydraulic cylinders, every detail counts, from the cylinder bore size to the hydraulic cylinder stroke length.

Impact of Incorrect Measurements

Incorrect measurements can have far-reaching consequences. A cylinder that doesn’t fit correctly might not only cause mechanical issues but could also lead to safety hazards. For instance, a misfitted cylinder might cause a machine to operate unpredictably, posing risks to operators and surrounding equipment. This is why understanding hydraulic cylinder specifications and dimensions is critical.

Tools Needed for Measuring Hydraulic Cylinders

Having the right tools at your disposal is half the battle won. Here’s a list of essential tools you’ll need

Measuring Tape or Calipers

A basic but essential tool, a measuring tape can help you measure the hydraulic cylinder dimensions like length and diameter. However, for more precision, especially in industrial applications, calipers are recommended. Calipers are particularly useful for measuring cylinder rod diameter and cylinder bore size with high accuracy.

Vernier Calipers

For those who need to measure small components like the rod diameter or bore size, Vernier calipers are the go-to tool. They provide precise measurements, which are crucial for ensuring the cylinder fits perfectly within your hydraulic system.

Measuring Rods and Extensions

These tools are particularly useful for measuring the internal components of the cylinder, like the hydraulic cylinder stroke length. Measuring rods can reach into the cylinder, providing accurate measurements even in hard-to-reach areas.

How to Measure a Hydraulic Cylinder for Seal Kit?

When replacing or repairing a hydraulic cylinder, one of the key components you’ll need to measure is the seal kit. Accurate measurements ensure that you select the correct seal kit, which is crucial for the cylinder’s performance and longevity. The following steps will guide you on how to measure hydraulic cylinder components for a seal kit.

Step 1: Measuring the Rod Diameter

Use a caliper to measure the diameter of the rod at several points along its length to ensure accuracy. This measurement will help you choose the correct rod seal and wiper.

Step 2: Measuring the Bore Size

Insert the caliper or inside micrometer into the cylinder to measure the internal bore diameter. This measurement is essential for selecting the correct piston seal.

Step 3: Measuring the Groove Width and Depth

Measure the width and depth of the seal grooves where the seals sit. This ensures that the new seals will fit properly, maintaining the cylinder’s efficiency.

How to Measure Hydraulic Cylinder Bore?

Measuring the bore size of a hydraulic cylinder is one of the most critical measurements you can take. The bore size directly impacts the force that the cylinder can generate and is essential in determining hydraulic cylinder size.

Use an inside micrometer or a bore gauge to measure the internal diameter of the cylinder.

Ensure the tool is properly calibrated and inserted into the cylinder before expanding it to fit snugly against the cylinder walls.

Take multiple measurements at different points to check for consistency and roundness of the cylinder.

How to Measure Hydraulic Cylinder Stroke Length?

The stroke length is the distance the piston travels inside the cylinder, which determines the range of movement for the hydraulic system. Measuring hydraulic cylinder stroke length accurately is crucial for ensuring the cylinder’s performance matches its intended use.

Fully extend the cylinder rod to its maximum length.

Measure from the base of the cylinder (where the rod is attached) to the tip of the rod.

This measurement gives you the stroke length, which is crucial for understanding the cylinder’s operational capacity.

Step-by-Step Guide to Measuring a Hydraulic Cylinder

Now that you’re equipped with the necessary tools, let’s walk through the measurement process step by step, covering all essential hydraulic cylinder dimensions.

Measuring the Retracted Length

The retracted length is the length of the cylinder when the rod is fully inside. Hydraulic cylinder retraction length is a critical dimension, especially when space constraints are a factor.

Retract the rod completely into the cylinder.

Measure the entire length of the cylinder from end to end.

Record this measurement as the retracted length.

Measuring the Extended Length

The extended length is the total length of the cylinder when the rod is fully extended. Hydraulic cylinder extension length is essential for understanding the full range of movement your cylinder can achieve.

Fully extend the rod out of the cylinder.

Measure the total length from one end of the cylinder to the other.

This gives you the extended length.

Common Mistakes to Avoid

Even with the best tools and intentions, mistakes can happen. Here’s how to avoid them and ensure precision measurement of hydraulic cylinders:

Misreading Measurements

One common error is misreading the measurements, especially with complex tools like Vernier calipers. Always double-check your readings and make sure you understand how to use the tool properly.

Using Incorrect Tools

Using the wrong tools can lead to inaccurate measurements. Ensure you have the right tools for each specific measurement task, as outlined in our hydraulic cylinder sizing guide.

Measuring a hydraulic cylinder accurately is essential for maintaining the efficiency and safety of your hydraulic systems. By following this guide and avoiding common pitfalls, you can ensure that your measurements are precise, leading to better performance and a longer lifespan for your equipment. Understanding the different hydraulic cylinder specifications and dimensions, from stroke length to cylinder bore size, will help you keep your system running smoothly.