Excavators are among the most versatile and essential machines in the construction industry and various other sectors. Their ability to perform a wide range of tasks makes them indispensable on any job site. In this article, we will explore the different types of excavators, their specific uses, how they compare to other heavy machinery like backhoes, and the importance of key components such as the hydraulic cylinder and cylinder barrel. Additionally, we will discuss the safety considerations when operating these machines and the factors to consider when deciding whether to rent or buy an excavator.

Types of Excavators

Crawler Excavators

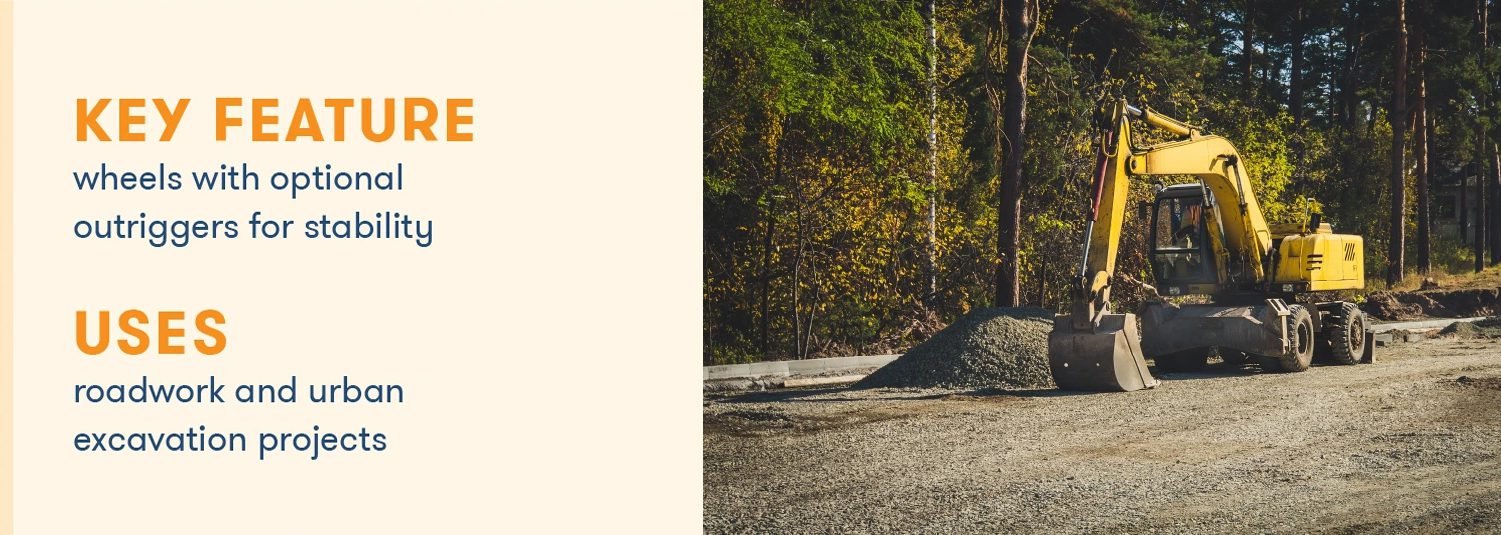

Wheeled Excavators

Wheeled excavators are similar to crawler excavators but are mounted on wheels instead of tracks. This makes them more maneuverable and faster on paved surfaces or hard ground. Wheeled excavators are often used in urban environments or on jobs that require frequent movement across the site. The flexibility of the hydraulic cylinder in these machines allows for quick adjustments and smooth operation, even on rough terrain.

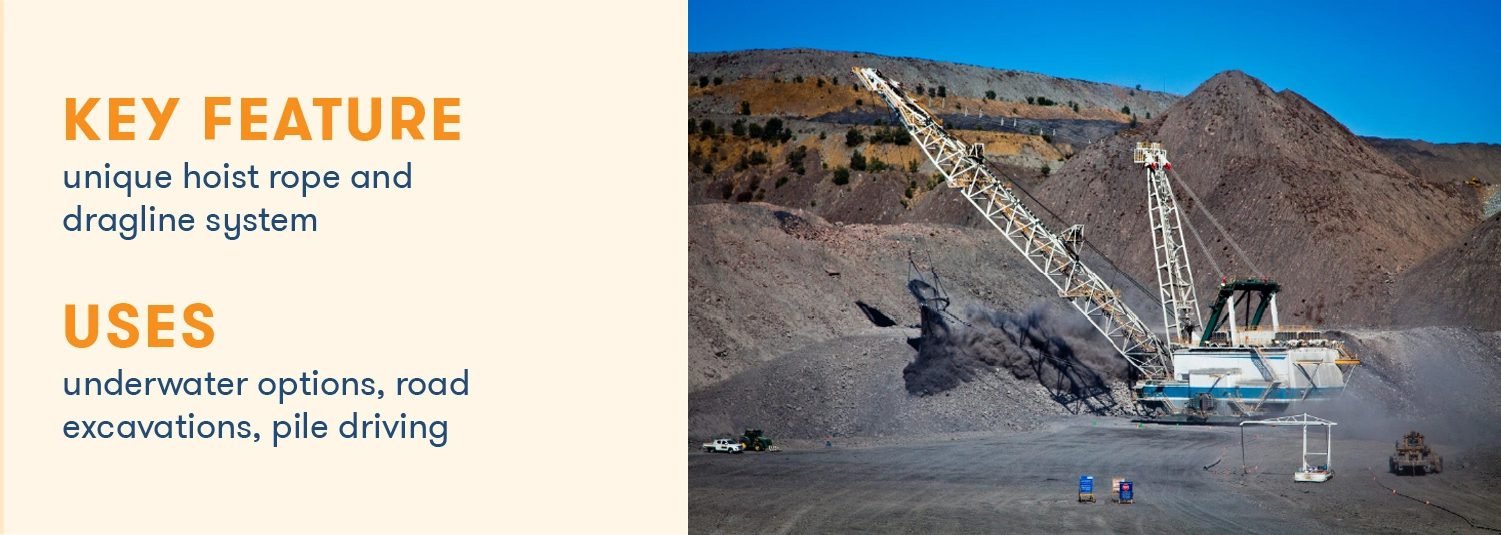

Dragline Excavators

Dragline excavators are primarily used in large-scale projects such as mining or dredging. These machines have a long boom with a suspended bucket that is dragged across the material to be excavated. The hydraulic system, including the cylinder barrel, is essential for controlling the precise movements of the dragline, ensuring that large volumes of material can be moved efficiently.

Suction Excavators

Suction excavators, also known as vacuum excavators, use high-powered suction to remove materials from the ground. These machines are ideal for delicate jobs where precision is required, such as when working around underground utilities. The hydraulic cylinder controls the movement of the suction arm, allowing for accurate positioning and efficient material removal.

Skid Steer Excavators

Skid steer excavators are compact machines known for their versatility and maneuverability in tight spaces. They are commonly used for small-scale excavation tasks, landscaping, and site preparation. The hydraulic system in skid steer excavators is vital for the smooth operation of the arm and attachments, ensuring that the machine can handle a variety of tasks with ease.

Long Reach Excavators

Long reach excavators are designed for jobs that require extended reach, such as demolition or working in hard-to-reach areas. These machines have a longer boom and arm, allowing them to access areas that standard excavators cannot. The hydraulic cylinder, with its robust cylinder barrel, ensures that the extended arm can perform heavy lifting and precise movements without compromising stability.

Mini Excavators

Mini excavators, also known as compact excavators, are small yet powerful machines used for tasks in confined spaces. They are popular in urban construction, landscaping, and utility work. The hydraulic system in mini excavators, particularly the cylinder barrel, is designed to deliver maximum power in a compact form, enabling these machines to perform efficiently in tight quarters.

What Are Excavators Used For?

Excavators are incredibly versatile and are used in a wide range of applications beyond just digging. Here are some of the most common uses of excavators:excavators are used for a variety of tasks, including digging foundations, trenches, and holes. They are also used for lifting and placing heavy materials, demolishing structures, and grading the land. The hydraulic cylinder’s power is crucial in handling the heavy loads and performing precise movements required in construction.

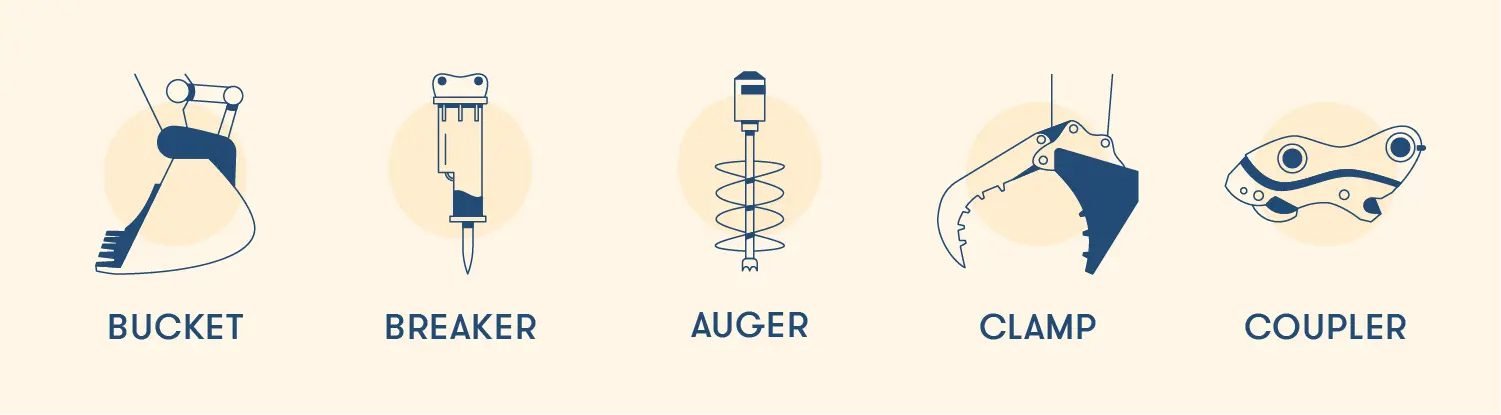

Demolition

Excavators are often equipped with specialized attachments such as hydraulic breakers or shears to handle demolition tasks. These machines can tear down buildings, crush concrete, and remove debris. The cylinder barrel in the hydraulic system is designed to withstand the extreme forces generated during demolition work.

Material Handling

Excavators are used in material handling tasks, such as loading and unloading trucks, moving materials around the site, and sorting debris. The hydraulic system allows for smooth and controlled movements, ensuring that materials are handled efficiently and safely.

Mining

In mining operations, excavators are used to remove overburden, dig trenches, and extract valuable minerals from the earth. The robust design of the hydraulic cylinder and cylinder barrel ensures that the excavator can operate in harsh conditions and handle the heavy loads associated with mining.

Forestry

In forestry, excavators are used for tasks such as tree felling, log handling, and land clearing. The hydraulic system’s precision and power are essential for handling large trees and heavy logs, making the excavator an indispensable tool in forestry operations.

Landscaping

Excavators are commonly used in landscaping for tasks such as digging ponds, shaping terrain, and installing hardscapes. The compact size and maneuverability of mini excavators make them ideal for residential landscaping projects, while the hydraulic system ensures that the machine can perform delicate tasks with precision.

Snow Removal

In regions with heavy snowfall, excavators are used for snow removal. The hydraulic system allows for the attachment of snowplows or blowers, making the excavator a versatile tool for clearing roads, driveways, and parking lots.

Disaster Cleanup

After natural disasters such as hurricanes, earthquakes, or floods, excavators are used to clear debris, remove fallen trees, and assist in search and rescue operations. The hydraulic cylinder’s durability is crucial in these situations, as the machine must operate continuously in challenging conditions.

Dredging

Dredging involves removing sediment and debris from the bottom of bodies of water, such as rivers, lakes, or harbors. Excavators equipped with long reach arms are often used in dredging operations to maintain waterway depth and prevent flooding. The hydraulic system ensures that the machine can operate efficiently in wet and muddy conditions.

Underwater Operations

In addition to dredging, excavators are also used in other underwater operations, such as laying pipelines or installing underwater structures. The hydraulic cylinder’s water-resistant design is essential for maintaining performance in these challenging environments.

Road Construction

In road construction, excavators are used to dig trenches for utilities, grade the land, and remove old pavement. The versatility of the hydraulic system allows the excavator to switch between tasks quickly, making it an essential machine for road construction projects.

Excavator vs. Backhoe

While both excavators and backhoes are used for digging and material handling, they differ significantly in design, size, and functionality.

Design and Size

Excavators are generally larger and more powerful than backhoes. They have a 360-degree rotating cab and are typically mounted on either tracks or wheels. The hydraulic cylinder in excavators is designed to handle more significant loads and provide greater digging depth than backhoes.

Functionality

Excavators are more versatile in terms of attachments and can perform a wider range of tasks. Backhoes, on the other hand, are often used for lighter digging tasks and material handling. The cylinder barrel in backhoes is typically smaller, reflecting the machine’s more limited capacity.

Preferred Situations

Excavators are preferred for large-scale construction projects, mining, and demolition, where power and reach are critical. Backhoes are more commonly used in smaller construction projects, landscaping, and agricultural work. The hydraulic system in both machines is tailored to their specific tasks, with excavators offering more power and flexibility.

Operating an Excavator Safely

Safety is paramount when operating an excavator. Operators must be trained to use the machine correctly and understand the limits of the hydraulic system. Regular maintenance of the hydraulic cylinder and cylinder barrel is essential to prevent malfunctions and ensure safe operation. Additionally, operators should always be aware of their surroundings and use appropriate safety equipment, such as seat belts and hard hats.

Renting vs. Buying Excavators

When deciding whether to rent or buy an excavator, several factors must be considered.

Considerations for Deciding to Rent or Buy

The decision to rent or buy depends on the frequency of use, the type of projects being undertaken, and the availability of capital. Renting an excavator is often more cost-effective for short-term projects, while buying is more economical for long-term use. The condition and maintenance of the hydraulic system, particularly the cylinder barrel, should also be a factor in the decision, as it directly impacts the machine’s performance and longevity.

Pros and Cons

Renting offers flexibility and lower upfront costs but may be more expensive in the long run. Buying provides the advantage of ownership and the ability to customize the machine with specific attachments. However, it requires a significant initial investment and ongoing maintenance costs. The condition of the hydraulic cylinder is a critical factor in the overall cost of ownership, as repairs can be expensive.

Excavators are powerful and versatile machines that play a critical role in various industries. From construction and demolition to mining and disaster cleanup, excavators are essential tools for completing a wide range of tasks efficiently and safely. The hydraulic system, including the hydraulic cylinder and cylinder barrel, is the heart of the excavator, providing the power and precision needed for its operation. Whether renting or buying, understanding the different types of excavators and their specific uses is crucial for making informed decisions and ensuring the success of your projects