Have you ever wondered what makes certain metal rods exceptionally shiny and durable? That’s the magic of chromium plating. In this article, we’re diving deep into the world of chromium plated rods, exploring their benefits, applications, and much more.

What is a Chromium Plated Rod?

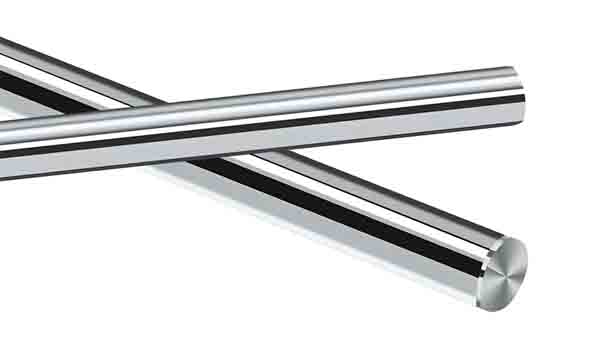

A chromium plated rod is essentially a metal rod that has been coated with a thin layer of chromium through an electroplating process. This coating provides numerous benefits, including enhanced durability, corrosion resistance, and a sleek, polished appearance.

Importance of Chromium Plating

Chromium plating is crucial in various industries due to its ability to significantly extend the lifespan of metal components. This process not only protects the underlying metal but also improves its performance in demanding environments.

Understanding Chromium Plating

Definition and Process

Chromium plating involves electroplating a layer of chromium onto a metal object. The process starts with thorough cleaning and preparation of the surface, followed by the electroplating itself, which involves submerging the metal rod in a chromium solution and applying an electric current to facilitate the coating.

History of Chromium Plating

The technique of chromium plating dates back to the early 20th century. Initially developed for decorative purposes, it quickly found applications in industrial settings due to its protective qualities.

Benefits of Chromium Plated Rods

Durability and Strength

One of the standout benefits of chromium plated rods is their enhanced durability. The chromium layer acts as a shield, protecting the metal from wear and tear, which is particularly valuable in high-stress applications.

Corrosion Resistance

Chromium is highly resistant to corrosion, making it an ideal coating for rods used in environments exposed to moisture and chemicals. This resistance helps prevent rust and extends the rod’s lifespan.

Aesthetic Appeal

Beyond functionality, chromium plating provides a lustrous, reflective finish that is aesthetically pleasing. This shiny appearance is often desirable in decorative applications.

Applications of Chromium Plated Rods

Automotive Industry

In the automotive sector, chromium plated rods are used in various components, including shock absorbers and steering systems, due to their strength and corrosion resistance.

Aerospace Sector

The aerospace industry relies on chromium plated rods for their lightweight and durable properties, which are essential for aircraft components that must withstand extreme conditions.

Hydraulic and Pneumatic Systems

Chromium plated rods are a staple in hydraulic and pneumatic systems. Their smooth surface reduces friction, improving the efficiency and lifespan of these systems.

Industrial Machinery

In industrial machinery, chromium plated rods are used in a variety of applications, from manufacturing equipment to heavy-duty machinery, thanks to their robust performance.

Chromium Plating Process

Surface Preparation

The first step in the chromium plating process is surface preparation. This involves cleaning the rod to remove any impurities that could affect the adhesion of the chromium layer.

Plating Procedure

The actual plating involves submerging the rod in a chromium solution and applying an electric current. This causes the chromium ions to bond with the metal surface, creating a thin, uniform layer.

Quality Control and Inspection

After plating, the rods undergo rigorous quality control and inspection to ensure the coating is even and free from defects. This step is crucial to guarantee the rod’s performance and longevity.

Types of Chromium Plating

Hard Chromium Plating

Hard chromium plating, also known as industrial chromium plating, provides a thick, wear-resistant layer. It’s commonly used in applications where durability is paramount.

Decorative Chromium Plating

Decorative chromium plating, on the other hand, is thinner and primarily used for aesthetic purposes. It offers a shiny finish but doesn’t provide the same level of protection as hard plating.

Challenges in Chromium Plating

Environmental Concerns

Chromium plating poses environmental challenges due to the hazardous chemicals involved. Proper disposal and treatment of waste are essential to minimize environmental impact.

Technical Difficulties

Achieving a uniform and defect-free coating can be technically challenging. Factors like temperature, current density, and plating time must be meticulously controlled.

Innovations in Chromium Plating

Advanced Techniques

Recent advancements in chromium plating technology include the development of more efficient and environmentally friendly processes, such as trivalent chromium plating.

Sustainable Practices

The industry is also adopting sustainable practices, such as recycling plating solutions and using less harmful chemicals, to reduce the environmental footprint of chromium plating.

Maintenance of Chromium Plated Rods

Regular Cleaning

To maintain their appearance and performance, chromium plated rods should be regularly cleaned to remove dirt and contaminants that could damage the surface.

Preventive Measures

Applying protective coatings and using the rods in suitable environments can further extend their lifespan and maintain their quality.

Choosing the Right Chromium Plated Rod

Factors to Consider

When selecting a chromium plated rod, consider factors like the intended application, environmental conditions, and required durability to ensure you choose the right type.

Industry Standards

Adhering to industry standards and specifications is crucial to guarantee the rod’s performance and compatibility with other components.

Cost Considerations

Initial Investment

While chromium plated rods may have a higher initial cost, their durability and low maintenance requirements often result in long-term savings.

Long-term Savings

The extended lifespan and reduced need for repairs or replacements can make chromium plated rods a cost-effective choice in the long run.

Common Myths about Chromium Plated Rods

Debunking Misconceptions

There are several misconceptions about chromium plated rods, such as the belief that they are prone to peeling or that they are purely decorative. In reality, when properly manufactured and maintained, they are incredibly durable and functional.

Case Studies

Success Stories

Numerous industries have reported significant improvements in performance and longevity after switching to chromium plated rods. For example, a manufacturing company reduced downtime and maintenance costs by 30% after implementing these rods.

Lessons Learned

These case studies highlight the importance of proper selection, installation, and maintenance to maximize the benefits of chromium plated rods.

Future of Chromium Plated Rods

Emerging Trends

The future of chromium plated rods looks promising, with emerging trends focusing on improved environmental sustainability and the development of advanced coatings that offer even greater durability.

Technological Advancements

Ongoing research and development are expected to lead to new technologies that will further enhance the performance and applications of chromium plated rods.

Chromium plated rods are a vital component in many industries, offering unmatched durability, corrosion resistance, and aesthetic appeal. By understanding the plating process, benefits, and applications, you can make informed decisions about their use. As technology advances, we can expect even more innovative solutions in the world of chromium plating.