Exploring the Significance of Ready to Honed Tubes | EASTAI

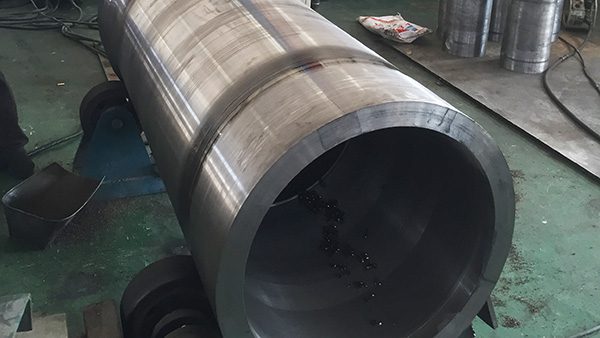

In the realm of precision engineering, one key component that stands out for its significance is the Ready-to-Honed Tube. These tubes, also known as cylinder tubes or smooth bore tubing, play a crucial role in various industries, ensuring optimal performance and reliability in hydraulic and pneumatic systems.

Understanding the Significance of Honed Tubes

Benefits of Using Ready-to-Honed Tubes

Ready-to-Honed Tubes are hailed for their manifold advantages. The seamless blend of precision, superior surface finish, and heightened resistance to wear and corrosion make them indispensable. These tubes are recognized for their dimensional accuracy and robustness, elevating their value in critical applications.

Applications Across Industries

The versatility of Ready to Honed Tubes is evident in their diverse applications across industries. From powering hydraulic cylinders in heavy machinery to facilitating pneumatic systems in the automotive sector, these tubes prove their mettle. The flawless surface finish and precise dimensions make them the go-to choice in applications demanding efficiency and reliability.

Delving into the Honing Process

Step 1: Initial Tube Inspection

Before the honing magic begins, a meticulous inspection of the initial tube is imperative. Only tubes meeting the highest quality standards proceed to the next stage, setting the foundation for precision.

Step 2: Pre-honing Preparation

The tube undergoes pre-honing preparations, a vital step that involves the removal of imperfections and irregularities. This meticulous process lays the groundwork for a flawless honing process.

Step 3: The Precision Honing Process

The actual honing process takes center stage, where the tube undergoes precision grinding to achieve the desired smoothness and dimensional accuracy. This step is pivotal, determining the tube’s performance and longevity in its final application.

The Materials Crafting Excellence

High-Quality Steel Grades for Resilience

Ready-to-Honed Tubes are crafted from high-quality steel grades, ensuring not just durability but a robust performance. The selection of the right steel significantly influences the overall functionality and longevity of these tubes.

Guarding Against the Elements: Types of Coatings

To enhance resistance against corrosion and wear, Ready-to-Honed Tubes may undergo various coatings. These protective layers not only shield the tube but also contribute to its functionality across different environments.

Choosing the Right Supplier Matters

Reputation and Experience as Benchmarks

Selecting a supplier with a solid reputation and ample experience is paramount. The supplier’s track record and customer testimonials serve as indicators of the quality of their products and services.

Quality Assurance and Certifications Ensure Reliability

Ensure the chosen supplier adheres to stringent quality assurance measures and possesses relevant certifications. This guarantees that the Ready-to-Honed Tubes meet industry standards and specifications.

Maintaining Excellence: Tips for Ready-to-Honed Tubes

Cleaning and Lubrication for Prolonged Lifespan

Proper maintenance is the key to extending the lifespan of Ready-to-Honed Tubes. Regular cleaning and lubrication prevent the accumulation of debris, ensuring smooth operation.

Steering Clear of Common Issues

Proactive identification and addressing of common issues, such as corrosion or abrasion, play a pivotal role in maximizing the performance of Ready-to-Honed Tubes.

Elevating Precision with Ready-to-Honed Tubes

In conclusion, Ready-to-Honed Tubes stand as a testament to precision engineering, offering a harmonious blend of durability, precision, and reliability. From understanding the honing process to selecting the right materials and suppliers, each aspect contributes to the optimal performance of these critical components.