Honed ID steel tubes are an essential component in hydraulic cylinder barrels, providing precision, strength, and durability for various industrial applications. Whether you’re new to the field of hydraulic systems or a seasoned professional, understanding the role these tubes play and how to choose the right one is crucial. In this article, we’ll take a deep dive into honed ID steel tubes, their importance, materials, manufacturing process, and more.

What is Honed ID Steel Tubes?

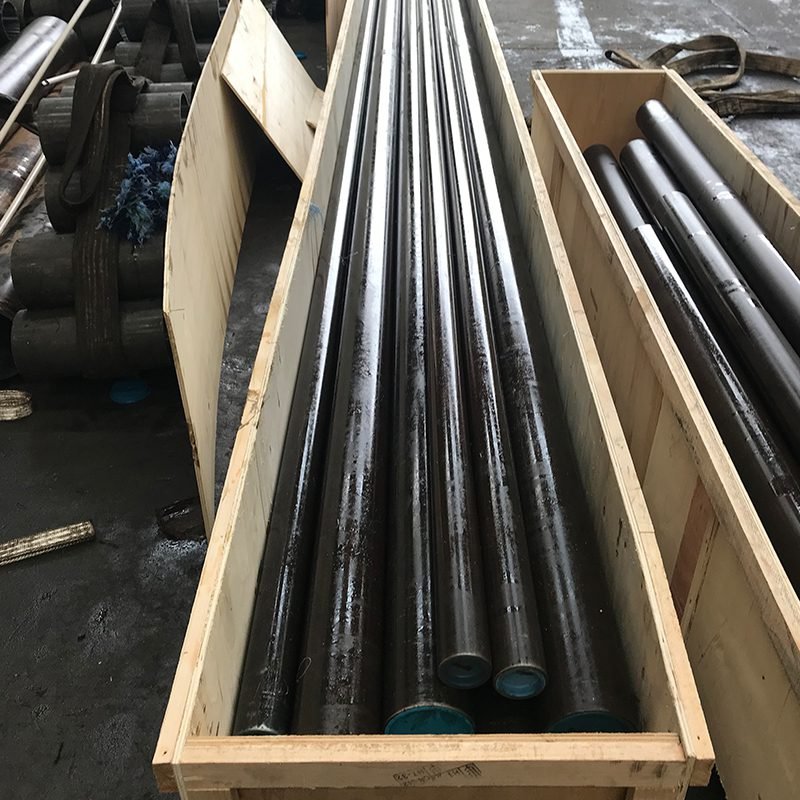

Honed ID steel tubes are seamless pipes that have been processed to have an exceptionally smooth interior surface. The «ID» stands for Inner Diameter, which is honed to a high degree of precision. This honing process makes these tubes perfect for applications where fluid or air needs to move smoothly without interruption — like in hydraulic cylinders.

What Are Hydraulic Cylinder Barrels?

Importance of Hydraulic Cylinder Barrels

Hydraulic cylinder barrels house the piston that moves within a hydraulic system. They are a key component in various heavy machinery, including construction equipment, manufacturing machines, and automotive systems. Without a perfectly smooth and precise surface, the piston inside the cylinder may not function properly, leading to leakage, inefficiency, and mechanical failures.

Typical Product Specifications for Hydraulic Cylinder Barrels

Hydraulic cylinder barrels, made from honed ID steel tubes, must meet specific requirements to ensure they function properly in hydraulic systems. Below is a table that outlines typical product specifications:

| Specification | Details |

| Material | Carbon Steel, Alloy Steel (e.g., ST52, 1020, 1045) |

| Inner Diameter (ID) | 30mm to 500mm (customizable) |

| Outer Diameter (OD) | Typically 40mm to 600mm (depends on ID and wall thickness) |

| Length | 2m to 12m (customizable) |

| Surface Roughness (ID) | Ra 0.2 to 0.4 µm |

| Wall Thickness | Typically 2mm to 20mm |

| Honing Precision | H7 to H9 (depends on requirements) |

| Yield Strength | Varies by material; generally 275 MPa to 600 MPa |

| Surface Treatment | Honed, Chrome Plated (if required) |

Why Use Honed ID Steel Tubes?

Honed ID steel tubes are specially designed to meet the demands of hydraulic cylinders. But what sets them apart from other types of steel tubes?

- Precision and Surface Finish: One of the main advantages of honed ID steel tubes is the precision they offer. The honing process smoothens the inner diameter of the tube, reducing friction between the piston and the cylinder wall. This ensures smooth movement and minimizes the risk of leaks.

- Durability and Strength: Honed ID steel tubes are built to withstand high pressures and heavy loads. The material used, typically carbon steel or alloy steel, is chosen for its ability to handle extreme forces without deforming or cracking.

Materials Used in Honed ID Steel Tubes

The choice of material is critical for the performance of honed ID steel tubes. Let’s explore the two most common materials used in their manufacturing.

Carbon Steel vs. Alloy Steel

Choosing between carbon steel and alloy steel for honed ID steel tubes is crucial for the performance of hydraulic cylinder barrels. Each material offers unique advantages depending on the application.

| Feature | Carbon Steel | Alloy Steel |

| Composition | Primarily contains carbon and iron. | Contains additional elements like chromium, molybdenum, etc. |

| Cost | Generally more affordable. | More expensive due to added alloying elements. |

| Strength | Strong but may become brittle at higher temperatures. | Higher strength and better performance under extreme conditions. |

| Corrosion Resistance | Lower resistance to corrosion, may require treatment. | Higher resistance to corrosion, especially with chromium or nickel content. |

| Heat Resistance | Moderate heat resistance, may weaken at high temperatures. | Excellent heat resistance, can withstand higher temperatures. |

| Durability | Suitable for most standard applications. | More durable in demanding or extreme environments. |

| Applications | Used in construction, general manufacturing. | Used in aerospace, automotive, and high-pressure environments. |

| Workability | Easier to work with and weld. | Requires more precision and specialized equipment for welding and fabrication. |

| Surface Treatments | Often requires protective coatings (e.g., galvanization). | May already contain elements that offer surface protection. |

As seen in the comparison, carbon steel is more cost-effective and commonly used in general manufacturing applications. However, alloy steel stands out in terms of strength, corrosion resistance, and performance under extreme conditions, making it ideal for specialized uses in high-pressure hydraulic systems or environments with extreme temperatures.

Quality Requirements for Hydraulic Cylinder Barrels

Hydraulic cylinder barrels must adhere to strict quality standards to ensure durability, precision, and reliable performance in hydraulic systems. Below are the common quality requirements and certifications:

- Honing Precision: The inner surface must be honed to precise tolerances (typically H7 to H9) to reduce friction and wear. This precision is essential to the functionality of hydraulic systems, where even minor deviations can cause significant performance issues.

- Surface Roughness: The inner surface roughness is usually maintained at Ra 0.2 to 0.4 µm to ensure smooth piston movement and prevent fluid leakage. A smooth finish is crucial to reducing friction and ensuring the long-term efficiency of the hydraulic cylinder.

- Material Strength: The material must have high yield and tensile strength, usually in the range of 275 MPa to 600 MPa, depending on application requirements. High material strength ensures that the barrel can withstand the intense pressures generated within a hydraulic system.

- Corrosion Resistance: Depending on the application, surface treatments like chrome plating may be necessary to protect against corrosion. In harsh environments, especially outdoors, corrosion resistance becomes critical to maintaining the integrity of the hydraulic cylinder.

- Certifications: It’s essential to verify that the supplier provides internationally recognized certifications, including:

- ISO 9001: Quality management certification.

- ISO 14001: Environmental management certification.

- ASTM A519: American standard for seamless carbon and alloy steel tubes.

- DIN 2391: German standard for precision steel tubes.

- REACH, RoHS: If environmental and safety compliance is required.

Manufacturing Process of Honed ID Steel Tubes

How are honed ID steel tubes made? The manufacturing process is highly specialized and involves several key steps.

Tube Honing Process

Honing is the process that sets these tubes apart. A honing machine uses abrasive stones to polish the interior surface of the tube, creating a smooth, accurate inner diameter. This step is critical to reducing friction and ensuring that the tube meets the necessary specifications for hydraulic applications.

Quality Control and Inspections

After honing, each tube undergoes strict quality control inspections. These tests ensure that the tube meets international standards like ISO or ASTM for precision, surface roughness, and material strength.

Applications of Honed ID Steel Tubes in Hydraulic Cylinders

Honed ID steel tubes are primarily used in hydraulic cylinders, but they also find applications in pneumatic cylinders, heavy machinery, and industrial equipment. These tubes are indispensable in any system that requires the transfer of pressurized fluids or air in a controlled manner.

Key Specifications to Consider When Buying Honed ID Tubes

Choosing the right honed ID steel tube for your hydraulic cylinder requires attention to several key specifications.

Inner Diameter (ID) and Outer Diameter (OD)

The inner diameter (ID) and outer diameter (OD) are critical dimensions that affect the tube’s compatibility with hydraulic cylinders. The ID must be precisely honed to fit the piston, while the OD needs to match the cylinder housing.

Wall Thickness and Length

The wall thickness and length of the tube determine its strength and ability to withstand pressure. Thicker walls offer more durability but may add weight, while longer tubes provide greater flexibility in larger hydraulic systems.

How to Source Honed ID Steel Tubes from China?

Sourcing honed ID steel tubes from China can be a cost-effective solution, but it’s important to follow a structured approach to ensure quality and reliability.

Steps to Find Reliable Suppliers

- Research & Shortlist: Start by researching suppliers on B2B platforms like Alibaba or Made-in-China. Look for companies with positive reviews and verified credentials.

- Request Quotes and Samples: Contact the shortlisted suppliers and ask for quotes and samples. Evaluate their response time, pricing, and product quality.

- Verify Certifications: Make sure the supplier provides internationally recognized certifications like ISO or ASTM.

- Negotiate Terms: Discuss payment terms, shipping methods, and lead times to ensure a smooth transaction.

- Customs & Importation: Ensure you have the correct HS code for the product and handle all customs regulations accordingly.

Honed ID steel tubes play a vital role in the smooth operation of hydraulic cylinders. Their precision, durability, and strength make them indispensable in various industrial applications. Whether you’re sourcing these tubes for manufacturing or repair, understanding the materials, specifications, and sourcing process will help you make informed decisions.

Download our product brochure here, and feel free to reach out if you find this information helpful!