How Does a Hydraulic Cylinder Work?

What Is a Hydraulic Actuator?

A hydraulic actuator is a device that converts hydraulic energy into mechanical motion. It’s a critical component in many machines and systems, enabling the movement of heavy loads with precision and power. Hydraulic actuators are commonly used in industries such as construction, manufacturing, and aerospace due to their ability to generate large amounts of force with relatively small inputs of hydraulic fluid.

How Does a Hydraulic Actuator Work?

Hydraulic actuators work by using pressurized hydraulic fluid to move a piston inside a cylinder. This movement generates linear force, which can be harnessed to perform various tasks such as lifting, pushing, or pulling. The process starts when hydraulic fluid is pumped into the cylinder, creating pressure that moves the piston. Depending on the design, the actuator can provide motion in one direction (single-acting) or in both directions (double-acting).

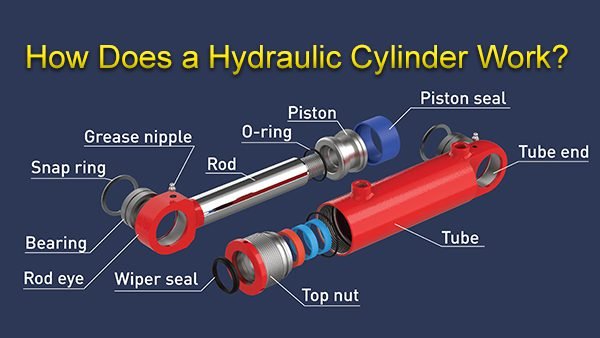

Hydraulic Cylinder Components

Understanding the components of a hydraulic cylinder is essential for grasping how the entire system functions.

Cylinder Barrel

The cylinder barrel is the main body of the cylinder, holding the hydraulic fluid and housing the piston. It must be strong enough to withstand high pressures without deforming or bursting.

Piston and Piston Rod

The piston is a solid disk that fits snugly within the cylinder barrel, dividing it into two chambers. The piston rod extends from the piston, passing through one end of the cylinder to transfer the generated force to the machine or device.

Seals and Gaskets

Seals and gaskets are crucial for maintaining pressure within the cylinder by preventing hydraulic fluid from leaking. They ensure that the system operates efficiently and safely.

Hydraulic vs Pneumatic Cylinders

While hydraulic and pneumatic cylinders perform similar functions, they operate on different principles and are suited to different applications.

Advantages of Hydraulic Cylinders

Hydraulic cylinders are known for their ability to generate higher forces, making them ideal for heavy-duty applications. They also offer more precise control over movement, which is essential in industries requiring exact positioning and handling of heavy loads.

When to Use Pneumatic Cylinders?

Pneumatic cylinders, on the other hand, use compressed air instead of hydraulic fluid. They are generally faster and more suitable for lighter loads and applications where speed is more critical than force, such as in automation systems.

Types of Hydraulic Cylinders

Hydraulic cylinders come in various types, each designed for specific applications.

Single-Acting Cylinders

Single-acting cylinders use hydraulic pressure to move the piston in one direction only. A spring or external force is required to return the piston to its original position.

Double-Acting Cylinders

Double-acting cylinders use hydraulic pressure to move the piston in both directions, providing greater control and versatility in applications where back-and-forth motion is required.

Telescopic Cylinders

Telescopic cylinders are designed for situations where a long stroke is needed but space is limited. These cylinders have multiple stages that extend sequentially, allowing for a compact design when retracted.

How To Choose a Hydraulic Actuator?

Selecting the right hydraulic actuator involves considering several factors, including the load, environmental conditions, and maintenance requirements.

Consideration of Load and Force

The load and force requirements are the primary factors in choosing a hydraulic actuator. The actuator must be able to generate enough force to move the load efficiently without exceeding the system’s capacity.

Environmental Factors

Environmental conditions such as temperature, humidity, and exposure to corrosive materials can affect the performance and lifespan of a hydraulic actuator. It’s important to choose an actuator that can withstand the specific conditions of the application.

Maintenance and Longevity

Some hydraulic actuators are easier to maintain than others. Consider the maintenance requirements and expected lifespan of the actuator, especially if it will be used in high-demand or hard-to-access locations.

Hydraulic cylinders are powerful devices that play a crucial role in many industrial applications. Understanding how they work, their components, and the differences between hydraulic and pneumatic systems can help you choose the right actuator for your needs. Whether you’re lifting heavy loads, operating machinery, or building complex systems, the right hydraulic cylinder can make all the difference.