When it comes to mechanical engineering and various industrial applications, precision and reliability are non-negotiable. One of the unsung heroes in this domain is the Precision Chrome Shaft. This article delves into the intricacies of precision chrome shafts, highlighting their importance, manufacturing process, benefits, applications, maintenance, and future trends.

What is a Precision Chrome Shaft?

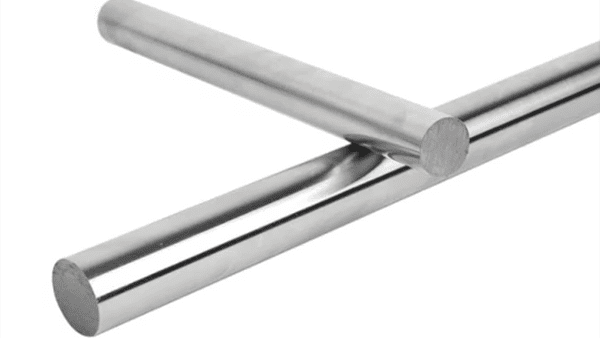

A precision chrome shaft is a rod-like component made from high-quality steel, coated with a layer of chromium. The chrome plating not only enhances the shaft’s appearance but also its durability, corrosion resistance, and overall performance. These shafts are meticulously engineered to meet exacting standards, ensuring seamless operation in a variety of applications.

Importance in Various Industries

Automotive Industry

In the automotive sector, precision chrome shafts are vital. They are used in various components such as steering columns, drive shafts, and shock absorbers. The precision and durability of these shafts ensure smooth and safe vehicle operation, contributing to overall vehicle performance and longevity.

Manufacturing Sector

The manufacturing industry relies heavily on precision chrome shafts for machinery and equipment. They play a crucial role in ensuring the efficiency and reliability of manufacturing processes, from assembly lines to heavy machinery. The strength and precision of these shafts help in maintaining production quality and reducing downtime.

Medical Equipment

Precision chrome shafts are also essential in the medical field. They are used in a range of medical devices, including surgical instruments and diagnostic equipment. The high precision and corrosion resistance of these shafts make them ideal for medical applications, where reliability and hygiene are paramount.

Manufacturing Process

Material Selection

The manufacturing process of a precision chrome shaft begins with the selection of high-quality steel. The chosen material must have excellent mechanical properties to withstand the demands of various applications. The steel is then meticulously processed to achieve the desired dimensions and surface finish.

Chrome Plating Process

Chrome plating is a critical step in the production of precision chrome shafts. The process involves electroplating a layer of chromium onto the steel shaft. This layer enhances the shaft’s hardness, corrosion resistance, and overall durability. The plating process requires precision and expertise to ensure a uniform and defect-free coating.

Quality Control Measures

Quality control is paramount in the manufacturing of precision chrome shafts. Each shaft undergoes rigorous testing and inspection to ensure it meets the required specifications. This includes dimensional checks, surface finish inspection, and testing for defects. Only shafts that pass these stringent tests are deemed fit for use.

Advantages of Precision Chrome Shafts

Durability and Longevity

One of the primary advantages of precision chrome shafts is their durability. The chrome plating significantly enhances the shaft’s hardness, making it resistant to wear and tear. This extends the shaft’s lifespan, ensuring long-term reliability.

Corrosion Resistance

Precision chrome shafts are highly resistant to corrosion. The chrome layer acts as a protective barrier, preventing rust and other forms of corrosion. This makes these shafts ideal for use in harsh environments and applications where moisture and chemicals are present.

High Performance

Precision chrome shafts are designed to deliver high performance. Their smooth surface and precise dimensions reduce friction, ensuring efficient operation. This makes them suitable for applications that require high-speed and high-precision movements.

Applications of Precision Chrome Shafts

Hydraulic Systems

In hydraulic systems, precision chrome shafts are used in hydraulic cylinders. They provide the necessary strength and precision for the smooth operation of these systems, ensuring reliable performance in various industrial applications.

Pneumatic Cylinders

Precision chrome shafts are also used in pneumatic cylinders. Their durability and smooth surface reduce friction, enhancing the efficiency and lifespan of these cylinders. This makes them ideal for applications in automation and manufacturing.

Industrial Robots

Industrial robots rely on precision chrome shafts for their movements. The high precision and low friction of these shafts ensure accurate and smooth operation, which is crucial for the performance of robotic systems in manufacturing and other industries.

Maintenance and Care

Regular Inspections

To maintain the performance and longevity of precision chrome shafts, regular inspections are essential. These inspections help identify any signs of wear or damage early, allowing for timely maintenance and repairs.

Proper Lubrication

Proper lubrication is crucial for the smooth operation of precision chrome shafts. Using the right lubricants helps reduce friction and wear, ensuring the shafts operate efficiently and last longer.

Choosing the Right Supplier

Quality Assurance

When selecting a supplier for precision chrome shafts, quality assurance is a critical factor. A reputable supplier should provide high-quality shafts that meet industry standards and specifications. This ensures you receive products that deliver reliable performance.

Customer Support

Good customer support is also important when choosing a supplier. A supplier that offers excellent customer service can assist with product selection, technical support, and after-sales service, ensuring a smooth and hassle-free experience.

Future Trends in Precision Chrome Shafts

Technological Advancements

The future of precision chrome shafts is bright, with ongoing technological advancements. Innovations in materials and manufacturing processes are expected to enhance the performance and durability of these shafts, making them even more reliable and efficient.

Environmental Considerations

As industries move towards sustainability, there is a growing focus on environmentally friendly manufacturing processes. This includes the use of eco-friendly materials and plating processes that minimize environmental impact. Precision chrome shafts are expected to evolve in line with these trends, offering greener solutions without compromising on performance.

Precision chrome shafts are indispensable components in various industries, offering unmatched durability, performance, and reliability. Their applications span from automotive to medical equipment, making them a crucial part of modern engineering. As technology advances and environmental considerations come to the forefront, the future of precision chrome shafts looks promising, with continued improvements in quality and sustainability.