About Us

We are a trusted supplier of a wide range of rods, chrome-plated honed tubes, hydraulic units, and cylinder tubes. Our product portfolio features chrome-plated rods, hollow piston rods, and other high-quality components designed to meet stringent performance and durability standards. We are dedicated to delivering exceptional products that exceed expectations in quality and reliability.

Delivery Capability

We Have Excellent Delivery Capabilities

We Are Available 24/7

Need Help? Contact Us Anytime

Satisfied Or Return

Easy 180-Day Return Policy

100% Secure Payments

We Pay 100% Safely

Why Choose EASTAI?

Since its establishment in 2006, EASTAI has been at the forefront of producing top-quality honing pipes, chrome rods for hydraulic and pneumatic cylinders, and customized hydraulic cylinders based on specific requirements.

With over 1,000 businesses trusting EASTAI, we have fostered growth and innovation across various industries. Our commitment to quality and excellence drives us to constantly improve and contribute to a better future.

Our Advantages

- Factory Direct Pricing

- Quality Assurance

- Comprehensive Quality Control

- Efficient Production Timelines

- Customized Manufacturing Solutions

Our Story

EAST AI was founded, primarily engaged in providing customers with comprehensive and well-integrated hydraulic and pneumatic technology solutions. In its initial stage, the company focused on manufacturing high-quality products.

The company moved to a new location covering an area of 5,000 square meters. With a significant improvement in performance, it gradually realized the integration of industry and trade.

EAST AI proposed a development strategy centered on "technological innovation as the core" and established comprehensive strategic partnerships with world-famous brands like Eaton, Komatsu, and Volvo.

In October, the company entered foreign markets such as Southeast Asia, Europe, the United States, and other countries, marking the beginning of its international trade.

Under the impact of COVID-19, we faced challenges of intense market competition and limited capital. Through the concerted efforts of the entire company, the total export trade volume exceeded 10 million US dollars.

With the continuous expansion of our industrial scale and to promote the development of the enterprise towards diversification, refinement, and technology, the EAST AI Group International Operations Center was established.

Key Markets and Share

Southeast Asia

North America

Europe

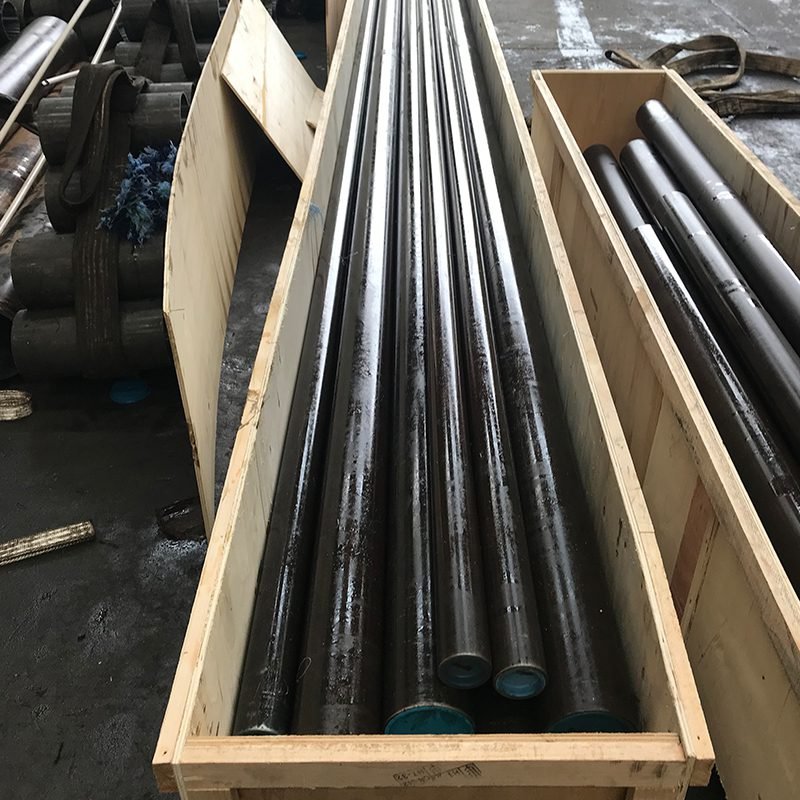

Chrome Bars

Our chrome-plated rods are distributed globally, catering to a wide range of applications, including hydraulic cylinder rods, mechanical shafts, and more.

Rich Manufacturing Experience

Over the years, we have honed our techniques, perfected our processes, and enhanced our craftsmanship to deliver products that consistently exceed expectations. With nearly 16 years of expertise in chrome-plated rod manufacturing, our factory stands as a testament to precision and quality.

Advanced Equipment and Facilities

Our production facility is equipped with state-of-the-art machinery, including cold drawing machines, honing machines, scraping and rolling machines, straightening machines, polishing machines, heat treatment furnaces, and grinding machines. Our team of professional engineers regularly maintains this equipment to ensure optimal performance and reliability.

High-Quality Raw Materials

We source our raw materials for chrome-plated shafts from renowned Chinese steel manufacturers, such as TPCO, Baosteel, and SHASTEEL, the largest steel bar producers in China. This guarantees a consistent supply of high-grade materials for our products.

High Precision

Our chrome rods are manufactured to exceptionally high precision, with tolerances of 7, 8, or 6. We also offer custom dimensions upon request to ensure the perfect fit and accuracy for your hydraulic cylinder or machinery needs.

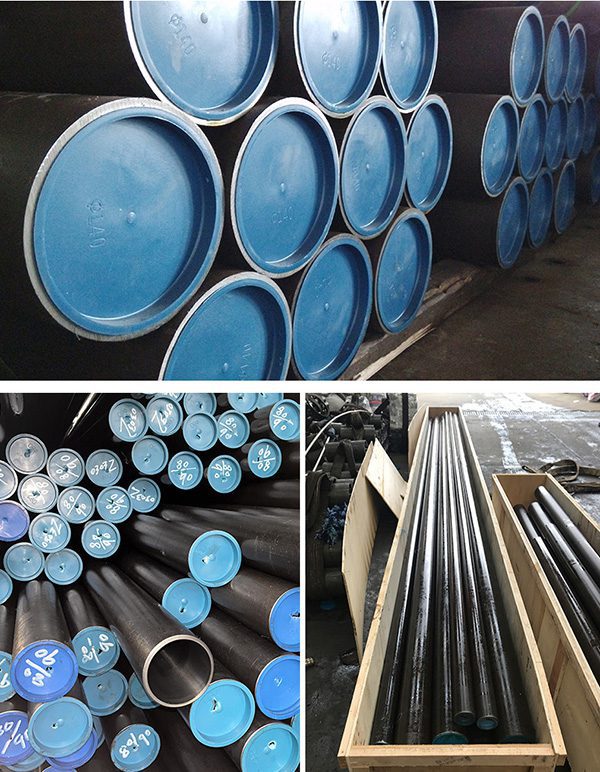

Honed Tubing

We have exported honed cylinder tubes to clients in numerous countries for use in hydraulic cylinders and other machinery components. Our products have earned a strong reputation among both domestic and international clients across the USA, Canada, Mexico, Colombia, Saudi Arabia, UAE, South Africa, Russia, Belarus, Thailand, Indonesia, Vietnam, Australia, Ukraine, Brazil, Turkey, South Korea, New Zealand, Singapore, Kuwait, and many more.

Rich Manufacturing Experience

Over the years, we have refined our techniques, perfected our processes, and enhanced our craftsmanship to deliver products that consistently exceed expectations. With over 16 years of expertise in chrome-plated rod manufacturing, our factory stands as a testament to precision and quality.

Advanced Equipment and Facilities

Our production facility is equipped with a wide range of advanced machinery, including cold drawing machines, cold rolling machines, honing machines, skiving and rolling machines, straightening machines, polishing machines, heat treatment furnaces, grinding machines, cutting machines, and more. Our team of professional engineers conducts regular maintenance to ensure all equipment operates at peak performance.

High-Quality Raw Materials

We source the raw materials for our honed cylinder tubes from renowned Chinese steel manufacturers, such as TPCO, SHASTEEL, and BAOSTEEL, the largest and most reputable steel producers in China

High Precision

Our honed tubes are manufactured to high precision, with tolerances of ISO H7, H8, H9, or H10, depending on size and customer requirements. This ensures the utmost accuracy for hydraulic cylinders.

Accreditation

Get In touch

Click now to see more case studies and learn about our client success stories!

Still on the fence? We totally understand. It's important to know about our real-life experiences before making any important decisions. Click here to explore more client case studies and see how they benefited from our services.

FAQ

ask us

anything

Q1: Are you a manufacturing company or a trading company?

A1: We are manufacturer and have nearly 10 years of experience in supplying metal materials and products in China.

Q2: How do we guarantee the quality?

A 2: We always make samples before mass production, and we do final inspection before shipment;

Q3: What is your payment method?

A3: 1.T/T: 30% deposit in advance and 70% balance before shipment.

2.T/T: 30% deposit in advance, balance 70% payable at sight.

3.After negotiation

Q4: Can you provide the certificate of the material?

A4: Yes, we can provide material testing certificate(MTC)(ISO9001) etc.

Q5: Can you provide samples?

A5: Yes, we can provide samples, but you need to pay the sample fee and shipping fee first. We will return the sample fee after you place the order.

Q6: Can you resolve issues such as clearing foreign exchange and customs?

Yes, We can resolve issues such as clearing foreign exchange and customs.