Exploring the World of Honed Tubes

In the realm of hydraulic systems, precision is paramount. Whether it’s for industrial machinery, automotive applications, or aerospace equipment, the performance and reliability of hydraulic systems hinge on the quality of their components. Among these crucial components, honed tubes stand out as indispensable elements that ensure optimal functionality and longevity.

Understanding Honed Tubes

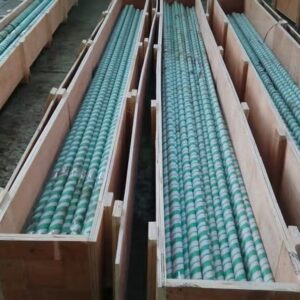

Honed tubes, also known as honed pipes or hydraulic cylinder tubes, are seamless tubes that undergo precision honing processes. This meticulous procedure involves the utilization of abrasive stones and tools to achieve a desired surface finish and dimensional accuracy. The result? A smooth inner surface with precisely controlled dimensions, free from imperfections and roughness.

Applications in Hydraulic Systems

Honed tubes find widespread usage in hydraulic systems, particularly in hydraulic cylinders. These cylinders are integral to various applications, including construction equipment, agricultural machinery, material handling systems, and more. By housing and guiding the piston within a hydraulic cylinder, honed tubes facilitate seamless movement, minimize friction, and ensure efficient energy transfer.

Quality Matters

When it comes to honed tubes, quality is non-negotiable. Inferior tubes can compromise the performance and reliability of hydraulic systems, leading to inefficiencies, downtime, and potential safety hazards. Therefore, it’s imperative to source honed tubes from reputable suppliers who adhere to stringent quality standards and employ advanced manufacturing processes.

Choosing the Right Supplier

With a plethora of honed tube suppliers in the market, selecting the right one can be daunting. However, certain criteria can help discern the best suppliers:

Experience and Expertise: Opt for suppliers with extensive experience and expertise in honed tube manufacturing. Seasoned suppliers possess the technical know-how and insights to deliver superior products that meet or exceed industry requirements.

Quality Assurance: Prioritize suppliers who prioritize quality assurance throughout the production process. This includes rigorous material inspections, precise machining techniques, and comprehensive testing procedures to ensure adherence to specifications and standards.

Customization Capabilities: Look for suppliers capable of offering customization options tailored to your specific hydraulic system requirements. Whether it’s bespoke dimensions, surface finishes, or material compositions, a supplier that can accommodate customization enhances compatibility and performance.

Certifications and Compliance: Verify that the supplier complies with relevant certifications and industry regulations. Certifications such as ISO 9001 demonstrate a commitment to quality management systems, while compliance with standards like ASTM and DIN ensures product integrity and reliability.

Customer Support: Evaluate the supplier’s customer support services, including pre-sales consultations, technical assistance, and after-sales support. A responsive and knowledgeable support team can address inquiries promptly and provide invaluable guidance throughout the procurement process.

In the intricate ecosystem of hydraulic systems, honed tubes play a pivotal role in ensuring precision, efficiency, and reliability. By partnering with reputable suppliers who prioritize quality, customization, and customer satisfaction, businesses can elevate their hydraulic systems’ performance and longevity. Invest in honed tubes of exceptional quality, and embark on a journey towards enhanced hydraulic solutions that surpass expectations.

In the dynamic landscape of hydraulic engineering, the significance of honed tubes cannot be overstated. Embrace precision, elevate performance, and embark on a seamless journey towards hydraulic excellence with top-tier honed tubes from trusted suppliers.