What’s Tilting Cylinders

Tilting cylinders are the unsung heroes of the forklift world, particularly in the realm of small tonnage operations. These pivotal components not only facilitate the precise movement of loads but also enhance the safety and efficiency of forklift operations.

The Role of Tilting Cylinders in Forklift Operations

Tilting cylinders enable the forklift mast to pivot forwards and backwards, allowing for a more controlled handling of goods. This capability is crucial for navigating tight spaces and ensuring load stability during transport.

Key Features of Tilting Cylinders

Durability, reliability, and precision control are the hallmarks of a quality tilting cylinder. These features are indispensable for the high demands of forklift operations.

Types of Tilting Cylinders

The two main types of tilting cylinders are hydraulic and pneumatic, each with its own set of advantages and disadvantages.

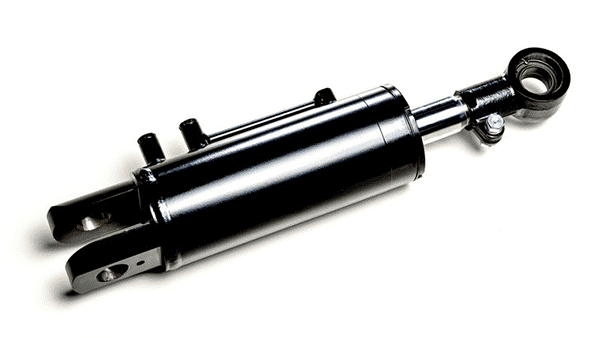

Hydraulic Tilting Cylinders

Hydraulic cylinders are known for their power and efficiency. They offer smooth operation and are ideal for heavy-duty applications.

- Advantages: High lifting capacity, precise control.

- Disadvantages: Potential for hydraulic fluid leaks, higher maintenance costs.

Pneumatic Tilting Cylinders

Pneumatic cylinders use compressed air for operation, making them lighter and easier to maintain.

- Advantages: Less maintenance, cleaner operation.

- Disadvantages: Lower lifting capacity, can be less stable.

Importance of Tilting Cylinders for Small Tonnage Forklifts

For small tonnage forklifts, tilting cylinders are crucial for enhancing maneuverability and improving load stability, ensuring that even lightweight forklifts can operate efficiently and safely.

Enhancing Maneuverability

The ability to tilt the mast allows forklifts to operate in more confined spaces, increasing the versatility of the vehicle.

Improving Load Stability

By adjusting the angle of the load, drivers can ensure that cargo is securely positioned, minimizing the risk of accidents.

Selection Criteria for Tilting Cylinders

When selecting a tilting cylinder, consider the size and capacity required for your operations, as well as the material durability and overall cost.

Size and Capacity

The size and lifting capacity of the cylinder must match the demands of your specific forklift model and the loads it will carry.

Material and Durability

Choose cylinders made from materials that can withstand the rigors of daily use, ensuring longevity and reliability.

Cost Considerations

While cost is an important factor, it should not be the sole criterion for selection. The overall value, including durability and maintenance costs, should be considered.

Installation and Maintenance

Proper installation and regular maintenance are key to maximizing the lifespan and efficiency of tilting cylinders.

Installation Tips

Follow manufacturer guidelines closely to ensure correct installation and avoid potential operational issues.

Maintenance and Troubleshooting

Regular checks and maintenance can prevent common issues and extend the service life of the cylinder.

Future Trends in Tilting Cylinder Technology

Innovations in tilting cylinder technology continue to evolve, with a growing emphasis on environmental considerations and efficiency.Innovations on the Horizon Innovations in tilting cylinder technology are geared towards enhancing efficiency, reducing environmental impact, and improving reliability. As we look to the future, expect to see advancements in materials science leading to lighter, stronger, and more durable tilting cylinders. Additionally, the integration of smart technologies will allow for better diagnostics, predictive maintenance, and more precise control, ultimately leading to smarter, more responsive forklift operations.

Environmental Considerations

The push towards sustainability is influencing the design and operation of tilting cylinders. Manufacturers are increasingly focusing on reducing energy consumption, minimizing hydraulic fluid leaks, and using environmentally friendly materials. This not only helps in reducing the carbon footprint but also in complying with stringent environmental regulations. Tilting cylinders play a critical role in the operation of small tonnage forklifts, providing the necessary flexibility and control to handle loads safely and efficiently. By understanding the types, key features, and selection criteria for

tilting cylinders, businesses can ensure they choose the right component for their needs. With advancements in technology and a growing focus on environmental sustainability, the future of tilting cylinder technology looks promising, offering potential for even greater efficiency and eco-friendliness in forklift operations.