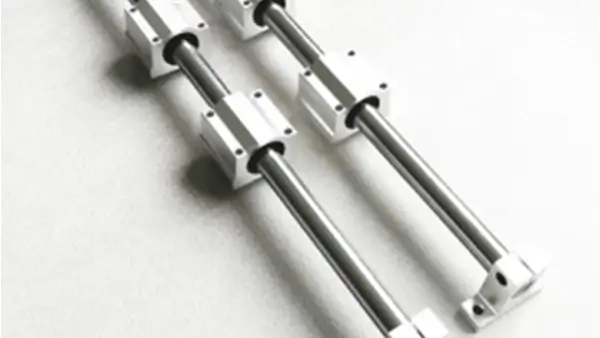

In the realm of mechanical engineering and design, the integrity of every component plays a pivotal role in the overall performance and longevity of machinery. Among these critical components, linear motion shafts stand out for their fundamental role in facilitating precise and smooth movements in a wide array of applications. This article delves into the significant enhancement that chrome bars bring to linear motion shafts, highlighting their benefits, types, applications, and maintenance insights.

Introduction to Linear Motion Shafts

Linear motion shafts are indispensable in translating rotational motion into linear motion in machinery. Their utilization spans across various sectors including industrial automation, automotive, aerospace, and robotics, underscoring their versatility and importance in modern engineering.

Why Chrome Bars?

The application of chrome bars in linear motion shafts brings about a superior level of durability and resistance to wear and tear. Chrome plating not only provides a harder surface but also offers excellent corrosion resistance, ensuring that the shafts maintain their precision over extended periods.

Types of Chrome Bars for Linear Motion Shafts

Among the types of chrome bars, hollow and solid variants are most common, each catering to specific needs based on weight, strength, and application requirements. Customization options further allow engineers to tailor chrome bars to the unique demands of their projects.

Applications of Chrome Bars in Linear Motion Shafts

Chrome bars are integral to the smooth operation of machinery in industrial automation, where precision is paramount. In the automotive industry, they contribute to the reliability and performance of vehicles. Robotics and aerospace are other fields where the properties of chrome bars are highly valued.

Installation and Maintenance

Proper installation and maintenance are key to maximizing the lifespan of chrome bars in linear motion shafts. Regular inspections and lubrication ensure optimal performance and prevent premature wear.

Purchasing Guide for Chrome Bars

Selecting the right chrome bar involves considering the application’s specific requirements and environmental conditions. Cost and supplier reputation also play crucial roles in the decision-making process.

Future Trends in Chrome Bars for Linear Motion Shafts

Technological advancements and a growing emphasis on sustainability are shaping the future of chrome bars in linear motion shafts. Innovations in materials and plating techniques hold the promise of even higher performance and environmental friendliness.

Chrome bars significantly enhance the functionality and durability of linear motion shafts. Their selection and maintenance require careful consideration, but the benefits they bring to machinery are undeniable. As technology progresses, we can anticipate even more improvements in the quality and sustainability of chrome bars.